Uncategorized

How to Target the Right Inventory Levels

Maintaining the right inventory levels is critical for businesses aiming for efficiency and profitability. In this guide, we’ll cover how to target the right inventory levels strategies for effective inventory control. By mastering these strategies, you can prevent overstock, avoid stockouts, and improve your bottom line. Read on to uncover practical tips for optimizing your inventory management.

Key Takeaways

- Effective inventory management requires balancing stock levels to meet customer demand while optimizing operational costs.

- Key Performance Indicators (KPIs), including inventory turnover ratio, fill rate, and service rate, are crucial for assessing and improving inventory performance.

- Adopting strategies like ABC analysis, Economic Order Quantity (EOQ) calculations, and just-in-time (JIT) management can significantly enhance inventory control and customer satisfaction.

Understanding Inventory Levels

The components of inventory comprise both finished goods ready for purchase and the raw materials necessary for production, each playing a critical role in revenue generation for businesses that sell tangible products. Upon establishing our company, it became apparent that proficient management of inventory quantities extended beyond simply possessing stock—it was crucial to maintain an optimal level. Products experiencing high customer demand can result in diminished loyalty and forfeited revenue opportunities if they become unavailable. Conversely, excessively low levels of inventory might lead to a decline in market presence and unattained sales profits.

To achieve this, businesses should develop a comprehensive inventory management plan that outlines key steps in the inventory management process and is continuously updated to adapt to changing conditions.

Effective control over inventory facilitates uninterrupted sales by aligning the receipt of stock with prevailing sales patterns, which bears significant consequences on working capital as well as business profitability. We recognized that sustaining balanced amounts within our inventories was not just vital to accommodate customer demand, but also central to cost optimization and confirming continuous operation viability for our business framework. The challenge lies in maintaining equilibrium. Excess stock immobilizes capital, while insufficient levels can provoke stockouts along with consequent loss in sales.

Inventory supervision is an intricate procedure surpassing mere tracking routines. It encompasses strategic planning including evaluating sales trends, projecting future consumer demands accurately, and executing prompt restocking practices. Such emphasis allows enterprises to curtail expenses effectively while mitigating instances where inadequate supply could disrupt potential transactions leading to enhanced fiscal results.

Dedicating time alongside resources into meticulously analyzing how we manage our stocks has yielded considerable benefits related directly to amplifying client satisfaction coupled with promoting operational proficiency within the confines of our enterprise operations.

Definition of Inventory Management

Inventory management is the systematic process of tracking, managing, and controlling inventory levels, encompassing raw materials, work-in-progress, and finished goods. This process involves monitoring inventory levels, identifying trends, and making necessary adjustments to optimize stock levels and reduce costs. Effective inventory management is critical for businesses to maintain optimal stock levels, reduce inventory costs, and improve customer satisfaction. By ensuring that inventory is accurately tracked and managed, businesses can avoid the pitfalls of overstocking or stockouts, leading to a more efficient and profitable operation.

Importance of Inventory Management

Inventory management is essential for businesses to ensure they have the right products in stock to meet customer demand. Poor inventory management can lead to stockouts, overstocking, and inventory obsolescence, resulting in lost sales, wasted resources, and decreased customer satisfaction. Effective inventory management helps businesses to reduce inventory costs, improve cash flow, and increase profitability. By accurately forecasting demand and maintaining optimal inventory levels, businesses can avoid the negative impacts of poor inventory control and ensure they are always ready to meet customer needs.

Benefits of Effective Inventory Management

Effective inventory management offers several significant benefits:

- Improved Customer Satisfaction: By having the right products in stock, businesses can meet customer demand promptly, leading to higher customer satisfaction and loyalty.

- Reduced Inventory Costs: Optimizing inventory levels helps businesses reduce costs associated with storage, handling, and maintenance of excess inventory.

- Improved Cash Flow: Reducing inventory levels frees up cash that is otherwise tied up in stock, allowing businesses to use these funds for other critical operations.

- Increased Profitability: By minimizing inventory costs and enhancing customer satisfaction, businesses can boost their profitability. Effective inventory management ensures that resources are used efficiently, contributing to the overall financial health of the business.

Key Performance Indicators (KPIs) for Inventory Control

Monitoring key performance indicators (KPIs) is crucial to evaluate the efficacy of a retailer’s inventory management process. KPI analysis has highlighted areas where our handling of inventory shines and those requiring enhancement. Essential KPIs, including the inventory turnover ratio, fill rate, and service rate, are pivotal for assessing both operational efficiency and customer satisfaction.

The significance of the inventory turnover ratio lies in its ability to reveal how frequently stock is sold and replenished within a certain timeframe. An elevated turnover ratio denotes proficient management of inventory coupled with strong sales vigor. Conversely, a diminished ratio could indicate an accumulation of unsold goods or overall sluggishness. Monitoring this metric allowed us to pinpoint underperforming products promptly leading us towards more strategic decisions regarding price reductions or product phase-outs.

In parallel, stand two other metrics: fill rate which captures the proportion of orders satisfactorily processed using available stock – thereby mirroring order fulfillment competency – while service rate measures how well the current stock satisfies consumer demand without culminating in shortages. Attending diligently to these indicators has been instrumental in optimizing our inventories ensuring minimal outages thus heightening client satisfaction.

Harnessing such insights into actionable strategies necessitates accurate decision-making tools. Herein lies the utility of robust software for managing inventories that automates tracking these vital statistics providing immediate access necessary for timely interventions aimed at preventing deficits as much as surpluses in supply making sure that our approach toward controlling stocks remains sturdy yet adaptable.

Inventory Turnover Ratio

The inventory turnover ratio is a key performance indicator (KPI) that measures how often a business sells and replaces its inventory within a specific period. It is calculated by dividing the cost of goods sold by the average inventory level. A high inventory turnover ratio indicates that a business is efficiently managing its inventory, selling and replenishing stock quickly. This can help reduce inventory costs and improve cash flow. Conversely, a low turnover ratio may suggest overstocking or slow-moving inventory, which can tie up capital and increase storage costs.

Implementing ABC Analysis

ABC analysis is a technique used to categorize inventory based on value, with an emphasis on items that hold the greatest significance for business. By applying this method, we were able to concentrate our efforts on products that have the most substantial impact in terms of sales and profitability. This approach is founded upon the 80/20 rule, which suggests that a minor fraction of goods accounts for the lion’s share of revenue and profit generation.

By employing ABC analysis, merchandise is segregated into three distinct groups:

- Category A constitutes about 15% of total stock yet it contributes to nearly 70% of overall sales figures. Items falling under this category are considered high-value and they play an essential role in driving company profits.

- Category B encompasses roughly 20% of inventory quantities but only attributes to around 20%of sales volume. These goods serve as significant assets but do not possess as much influence as Category A commodities.

- Category C, making up approximately 65% percent of inventory, nonetheless results in just about 10% percent contributions toward total sales earnings .These particular products are deemed low-value with minimal relevance regarding profitability margin.

Through routine classification using ABC analysis across all product lines, us in precision management of ordering volumes and timing intervals for each group with diligent attention towards fulfilling consumer needs for Category A through conscientious inventory control, adequate care given intermediately toB type goods, and basic handling foreseen in category C selections.This strategy has allowed us to enforce balance within stocked quantities, minimize holding expenditures, as well ascertain efficiency order processing times capable of satisfying clients expectations effectively.

Economic Order Quantity (EOQ) Formula

The formula for Economic Order Quantity (EOQ) assists enterprises in identifying the most efficient order quantity to reduce overall inventory costs while still fulfilling consumer needs. Determining EOQ was akin to fitting pieces together in a complex game, striving to achieve an equilibrium between ordering and holding expenses that result in cost-efficient inventory levels.

Recognizing that demand, along with ordering and holding charges, remains constant over time is intrinsic to EOQ’s approach. Although this may not consistently mirror actual market conditions, it acts as an essential benchmark for devising an inventory management strategy. Take the case where a store sells 1,000 jeans each year at a carrying cost of $5 per pair and placing an order incurs a $2 expense. Utilizing the EOQ reveals that ordering about 28 pairs at once strikes the best balance between minimizing expenses and satisfying customer requirements.

Utilizing the EOQ model has strengthened our ability to sustain ideal stock levels by preventing excessive surplus or shortages of goods on hand. By calculating both reorder points and required quantities more precisely, we have been able to streamline our process for replenishing inventory.

Incorporating these calculations into our operations not only slashed our costs related to maintaining inventory, but also enhanced cash flow management as well as bolstered our bottom line financially. The application of economic order quantity became foundational within our overarching plan concerning managing inventories—pivotal for guiding decisions toward ensuring sufficient supply without excess.

Safety Stock Calculation

Having safety stock serves as a safeguard against unanticipated surges in demand or postponements in shipments. Implementing it was akin to incorporating an insurance policy within our inventory system. Initial, we decided on setting the safety stock level at 50% of the lead-time demand, with plans to refine this figure by monitoring and learning from any incidents of stockouts.

To compute safety stock accurately involves measuring both peak daily sales and longest possible lead time, using this equation: Safety Stock = (peak daily sales x maximum lead time) – (average daily sales x normal lead time). As an illustration, if we encountered peak daily sales amounting to 100 units and a worst-case scenario of a 5-day delivery delay while typically achieving 80 unit-sales per day over a standard 3-day shipping duration. Then our calculation for safety would be:

Safety Stock = (100 units x 5 days) – (80 units x 3 days) = equivalent to saying that your buffer should consist of 260 extra items on top of regular inventory levels.

This computation is integral in identifying the reorder threshold, which signals when new orders must be placed—factoring both anticipated consumption during replenishment periods plus additional reserve—in order not to deplete essential merchandise stocks. Keeping suitable quantities as backup empowered us to effectively respond even amid sudden rises in customer demands thereby precluding potential dissatisfaction due to product unavailability.

Fine-tuning these buffer inventories based upon insights gained from past shortages along with market trends has been fundamental for refining our plan concerning inventory administration. This proactive approach enabled us strategically optimize just how much emergency supply was needed without succumbing excessive asset accumulation—a crucial step towards diminishing costs associated with keeping goods stocked while bolstering advancing promptness regarding client needs fulfillment thus elevating efficacy across all facets related to managing supplies.

Demand Forecasting Techniques

Ensuring precision in demand forecasting is key to effective inventory management. Forecasts that miss the mark can result in insufficient stock, damaging client relations and causing cost escalations. By leveraging historical sales figures to predict future buying behaviors, a clearer understanding emerges which guides better decision-making and sharper projections of sales.

The efficacy of forecasting models is bolstered by their dependence on historical sales information for refining predictions. Utilizing machine learning techniques such as regression analysis and decision trees allows us to discern patterns within past data more precisely. The incorporation of these technologies has markedly honed our prediction capabilities. Neural networks, particularly those that are recurrent, excel at recognizing intricate sequences in time-related data sets thereby enhancing forecast accuracy even further.

Employing machine learning for forecasts presents obstacles like ensuring high-quality data inputs and explaining model outcomes comprehensibly to stakeholders involved with inventory control. We dedicated efforts towards purifying our dataset and educating our workforce thoroughly on these methodologies’ intricacies—steps instrumental in optimizing predictive analytics capabilities which facilitate fine-tuning inventory strategies by foreseeing sale fluctuations accurately while also acknowledging market currents alongside seasonal shifts hence elevating prognostic fidelity dramatically.

Engaging suppliers actively into the forecast process aids significantly not just in warding off supply deficiencies, but also secures steadfastness regarding lead times. Through sharing advance insights about projected demands with partners supplying goods enabled us harmonize stocks adequately reflective of consumer needs whilst guaranteeing product availability when needed—a comprehensive strategy aimed at satisfying clientele expectations capably reducing occurrences where products run out excessively meanwhile prudent elevation upon managing overheads associated with keeping inventories occurs simultaneously through this integrated approach towards predicting customer purchases effectively resulting widespread benefits all-around within the chain’s systematics surrounding procurement processes.

Just-in-Time (JIT) Inventory Management

The Just-in-Time (JIT) approach to inventory management enables us to keep our stock levels low by arranging for materials to be delivered precisely when production is set to commence. Our adoption of JIT principles has revolutionized the way we manage our inventory, aligning it more closely with actual customer demand and thereby cutting costs, enhancing cash flow, and increasing overall operational efficiency.

In implementing JIT effectively, maintaining frequent communication with suppliers is essential. It helps solidify supplier relationships and optimize lead times. By cultivating robust partnerships with suppliers who are well-versed in our production schedules, they have been able to supply materials right on cue—a pivotal element in the triumph of our JIT strategy.

By adhering closely to lean manufacturing tenets that recommend eliminating unnecessary inventory, focusing instead on production based on immediate need has allowed us not only to streamline operations, but also significantly boost efficiency. The reduction of excess inventory limits waste while reducing storage expenses—simultaneously improving working capital—and makes adapting swiftly possible should changes in customer demands arise. This prevents both shortages and accumulation of obsolete stock.

Having put into practice a system like JIT means there’s a greater emphasis placed on accuracy within order fulfillment processes due to often having fewer goods stored as surplus. Hence why using perpetual inventory software has become integral for real-time monitoring of current stock volumes which assists us immensely—we can confidently satisfy ongoing orders without accumulating undue amounts of extra merchandise—striking an optimal balance central to upholding high standards in client satisfaction whilst fine-tuning our approach towards managing inventories.

Reducing Lead Times

Minimizing lead times is essential for maintaining an effective inventory management system and ensuring customer satisfaction. Extended lead times necessitate higher levels of safety stock, which in turn elevates associated expenses. Opting for suppliers in proximity has substantially cut down on lead time by circumventing lengthy transportation periods, thus enabling more prompt adaptation to fluctuations in market demand while simultaneously allowing a decrease in safety stock quantities.

Conducting performance evaluations of our suppliers and broadening the diversity within our supplier network has reinforced both reliability and robustness with regards to our inventory. Frequent appraisals guarantee that providers adhere to timelines as well as uphold quality standards. By spreading out reliance across multiple sources rather than just one, we’ve managed to diminish the potential hazards related to supply chain interruptions.

Adopting a strategy involving heightened order frequency contributes positively towards shorter lead durations and enhances rates at which inventory circulates (inventory turnover). This method supports sustaining reduced levels of stock while also minimizing storage-related costs—it aligns stored goods more closely with real-time demands from customers, thereby improving overall handling of our inventories.

All these efforts aimed at curtailing total lead time refine practices concerning managing inventories by reducing dependency on considerable amounts of safety stocks while heightening agility when responding to shifts within markets—such vigilant management renders our stocking systems nimble yet potent. It boosts satisfaction amongst customers alongside fine-tuning expenditure controls.

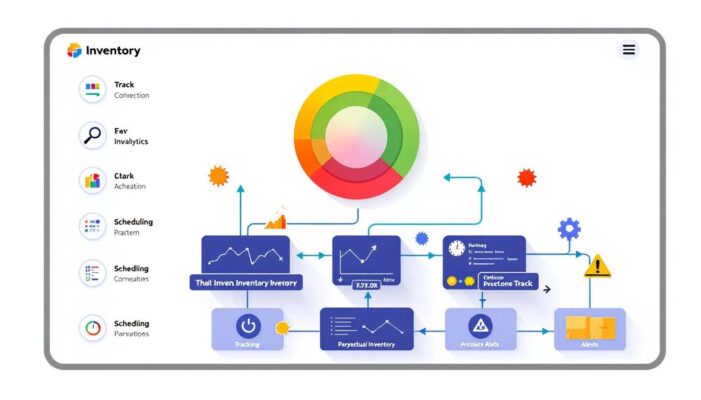

Perpetual Inventory System Implementation

The adoption of a perpetual inventory system has revolutionized our operational framework. This advanced inventory system ensures continuous monitoring and updating of stock quantities, providing current information at all times. Prior to its implementation, we faced challenges with inaccuracy and inconsistencies in our records. Now, this enhanced system promotes precision and diminishes errors, which significantly aids in strategic decision making.

Inherent technological attributes such as instantaneous updates and the utilization of barcode scanning are pivotal components within perpetual systems. These functionalities allow for meticulous tracking across every segment of our supply chain while maintaining updated databases constantly. Introducing this sophisticated system was not without hurdles. A staggered approach proved effective in overcoming initial difficulties by facilitating thorough staff education alongside assimilation into pre-existing operations.

Employing the perpetual inventory model has yielded significant gains throughout the organization’s structure: having immediate access to accurate stock levels equips us with valuable insight for establishing reorder thresholds and optimizing replenishment strategies effectively mitigating instances of both understocking or excessive inventories thereby streamlining overall management processes.

Barcodes and Radio Frequency Identification (RFID)

Barcodes and Radio Frequency Identification (RFID) are essential technologies for tracking and managing inventory levels. Barcodes are used to identify and track inventory items through scanning, while RFID uses radio waves to automatically identify and track tags attached to inventory items. These technologies enhance inventory accuracy, reduce manual errors, and streamline inventory management processes. By implementing barcodes and RFID, businesses can improve inventory accuracy, reduce inventory costs, and enhance customer satisfaction by ensuring that the right products are available when needed.

Reorder Point (ROP) Formula

The reorder point (ROP) formula is a crucial tool for determining when to reorder inventory to avoid stockouts and overstocking. It is calculated by multiplying the lead time by the average daily usage and then adding the safety stock level. The formula is as follows:

[ \text{Reorder Point (ROP)} = (\text{Lead Time} \times \text{Average Daily Usage}) + \text{Safety Stock} ]

This calculation helps businesses determine the optimal time to reorder inventory, ensuring that they maintain sufficient stock levels to meet customer demand without holding excessive inventory. By using the ROP formula, businesses can improve their inventory management, reduce costs, and enhance overall operational efficiency.

By integrating these new sections, the article now provides a comprehensive guide on targeting the right inventory levels for effective control, covering all essential aspects of inventory management.

Utilizing Inventory Management Software

Inventory management software has been instrumental in optimizing our supply chain processes. Technology solutions minimize lead times and improve inventory accuracy. Good software maintains the right stock levels with real-time data and task automation, resulting in fewer errors and more focus on strategic activities. An effective inventory management system can further enhance these benefits.

Investing in inventory management software streamlined workflows and enhanced lead time accuracy. Automation in order processing reduced errors and saved time, allowing staff to focus on other important tasks. Real-time data supported better forecasting and stock decision-making, optimizing inventory levels.

Integrating inventory management tools with other business systems enhances accuracy and data synchronization. For example, integrating our inventory management software with our ERP system improved visibility across all departments, facilitating better control. Cloud-based systems provided access to advanced solutions previously available only to larger enterprises.

The best inventory management solutions offer features like automated replenishment, cycle counting, and traceability. These features helped us avoid stockouts and reduce carrying costs. Using inventory management software, we achieved efficient management, improved order fulfillment, and enhanced overall performance.

Best Practices for Inventory Control

The implementation of superior inventory management strategies is crucial for the precise regulation of stock levels. Regular physical inventories maintain consistency between actual and logged quantities, minimizing variances while maintaining an optimal amount of merchandise.

By utilizing a perpetual inventory system, businesses can constantly track their stock to avoid shortages and minimize surplus goods. Analyzing sales patterns, including seasonal variations and product combinations, allows companies to make informed restocking choices that prevent excess inventory. Autonomous decision-making in replenishment activities ensures they are in line with business objectives.

Investing in comprehensive training programs is imperative to reap the full advantages offered by a perpetual inventory system. Such initiatives ensure employees effectively employ this system consistently. The adoption of uniform procedures for receiving new stocks contributes greatly to accuracy and reliability within the process. Detailed records on each item’s information like SKUs and barcodes have proven indispensable for more effective supervision over stock items.

Applying these practices has notably augmented operational efficiency, diminished costs associated with holding merchandise and sidestepped instances where goods were unavailable when needed—thereby perpetually refining our approach towards managing inventories, which directly bolsters customer satisfaction levels while fine-tuning our overall strategy concerning stocking methods.

Summary

To summarize, mastering inventory management is essential for the thriving and longevity of any enterprise engaged in handling physical goods. By honing in on optimal inventory levels, a business can fine-tune expenses, elevate customer satisfaction, and facilitate seamless operations. Essential tactics include monitoring inventory metrics accurately, tracking KPIs meticulously, applying ABC analysis strategically, and leveraging the EOQ model.

Precise safety stock calculations coupled with advanced demand forecasting methods are pivotal to refining inventory supervision. Diminishing lead times along with implementing continuous (perpetual) systems for managing stocks and exploiting sophisticated software specifically designed for controlling inventories underpin accurate upkeep of necessary stock quantities.

By adopting these methodologies and industry-leading practices faithfully will enable commanding oversight over your merchandise resources leading to trimmed costs as well as enhanced proficiency at fulfilling orders. As these measures become an integral part of your operation’s framework, you’ll notice that agility improves. Adaptability rises together with a bolstered capacity to cater to consumer needs efficiently.

Frequently Asked Questions

What do you mean by inventory?

Inventory refers to the physical stock of goods and materials that a business holds for sale to customers, essential for generating profit. This includes items in stores, warehouses, and even spare parts for repairs.

What is the most effective method for controlling inventory?

The most effective methods for controlling inventory include ABC analysis, Just-in-Time (JIT) inventory management, and the use of inventory management software. These approaches enable businesses to categorize items, minimize excess stock, and streamline operations efficiently.

How do you set target inventory levels?

To set target inventory levels effectively, analyze historical data and current trends to estimate future demand and supplier lead times, while also determining your desired service level to minimize stockouts.

This approach ensures you maintain adequate stock to meet customer needs efficiently.

What is the importance of maintaining balanced inventory levels?

It is crucial for a business to keep inventory levels well-balanced in order to effectively meet customer demand and optimize expenses, thus sustaining the operations of the business. This strategy improves operational efficiency and minimizes the chances of having excess inventory or experiencing shortages.

How does the Economic Order Quantity (EOQ) formula help in inventory management?

The EOQ formula is essential for businesses as it identifies the optimal order quantity that reduces total inventory costs while effectively meeting demand.

By balancing ordering and holding costs, it ensures efficient inventory management.

Contact us for additional support here