Fasteners, Uncategorized

Choosing the Right Gasket

Choosing the Right Gasket: A Comprehensive Guide

Choosing the right gasket is essential for preventing leaks and ensuring the efficiency of your system. Flange gaskets are a specific type of gasket designed to fit between sections of flared pipes, enhancing the contact surface area to ensure a secure seal. In this guide, we will explore the types of gaskets and key factors to consider for optimal performance.

Key Takeaways

- Selecting appropriate gasket materials, including rubber, metal, and composite options, is critical for preventing leaks and ensuring optimal performance in various applications.

- Key factors in gasket selection include temperature, pressure, media exposure, and environmental conditions; careful consideration can prevent failures and enhance durability.

- Regular testing and certification of gaskets, along with consulting experienced design engineers and suppliers, are vital for ensuring reliability and preventing common failure modes.

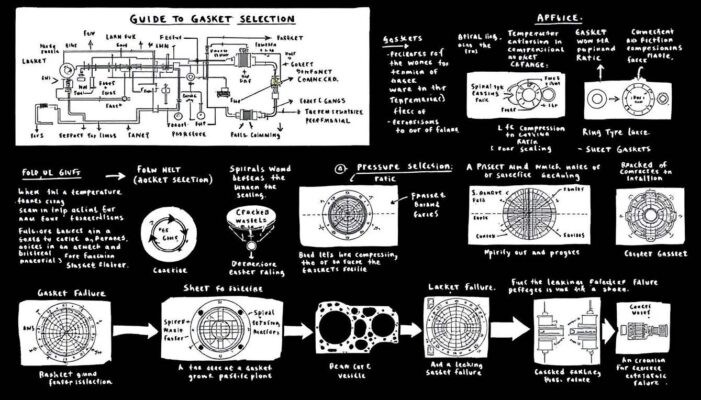

Understanding Gasket Materials

Selecting suitable gasket materials is essential for preventing leaks in mechanical systems and guaranteeing their enduring effectiveness. The characteristics of the chosen gasket material significantly impact its performance, making it crucial to choose an appropriate type based on your specific needs. Notable examples of gasket materials include those made from rubber, metal, and composite substances, each providing distinct advantages and suited for different uses.

Rubber gaskets are favored for their supple nature and durability, frequently appearing within automotive engines as well as various industrial machinery. Conversely, metal gaskets are sought after due to their robustness along with exceptional tolerance to both high temperatures and pressures – a perfect match for applications that must withstand intense conditions. Composite gaskets offer a blend of metallic strength combined with other fillers which confer superior sealing properties alongside versatility under fluctuating scenarios.

Spiral-wound gaskets often use generally a flexible graphite as a key filler material, enhancing the sealing capability while providing structural support.

Understanding the precise attributes and intended usage context of these various materials is fundamental when opting for one that ensures maximum effectiveness in terms of sealing ability. In subsequent segments below this discussion point’s surface, we will be scratching more thoroughly into each single kind amidst mentioned types regarding what sets them apart characteristic-wise and where they tend best fit application-wise.

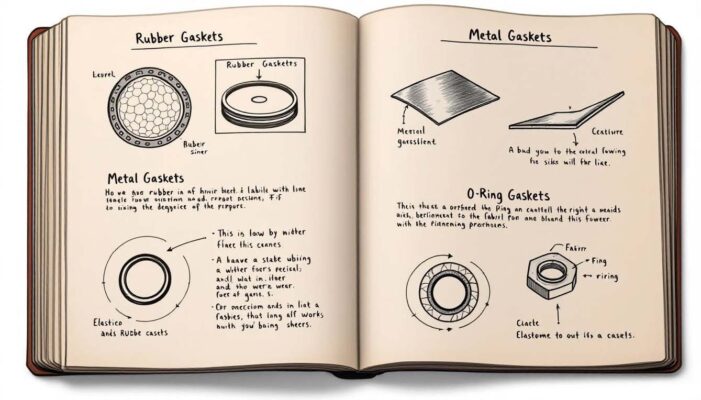

Rubber Gaskets

Rubber gaskets are viscoelastic, meaning their properties vary with temperature, becoming brittle in the cold and softening in high heat. Common types of rubber used for gaskets include Natural Rubber, Neoprene, Nitrile, and EPDM.

Neoprene gaskets are particularly notable for their thermal stability and resistance to water, chemicals, and corrosion, making them ideal for medical devices and various industrial applications. EPDM rubber gaskets stand out for their high resistance to heat and chemicals, maintaining good flexibility and durability in harsh environments.

Silicone rubbers are another popular choice due to their high-temperature resistance and low compression set, offering an extremely tight seal in various applications. When selecting rubber gaskets, consider their compatibility with encountered fluids to prevent chemical reactions and ensure durability.

Rubber gaskets are widely used in automotive engines and industrial equipment like pumps and valves due to their excellent flexibility and resilience.

Metal Gaskets

Metal gasket systems, including the common spiral wound gaskets and other varieties, are designed to endure high temperatures and pressures, ensuring reliability in demanding circumstances. Spiral wound gaskets excel in delivering a dependable seal for applications experiencing intense pressure. They utilize a V-shaped metal strip combined with malleable filler material for an optimal balance of durability and flexibility amidst variable conditions.

Some metal gaskets include an inner compression ring to improve sealing under extreme conditions by preventing gasket failure.

Frequently employed within high-pressure steam systems, among other settings subjected to severe temperatures and pressures, metal gaskets stand out due to their robust construction. Their capacity to sustain a consistent seal even under strenuous situations positions them as a favored option across numerous industrial uses.

Composite Gaskets

Composite gaskets, which meld metallic and filler materials together, bolster their ability to seal effectively while being versatile enough for different situations. This integration ensures they have enhanced toughness and longevity, thereby fitting a multitude of uses, particularly in scenarios that necessitate enduring heavy compression as well as resistance to chemicals.

Composite gaskets are made from a mix of metallic and filler material, where the metal provides structural support and the filler acts as the sealing element.

These gaskets stand out due to the malleability they provide, making them an ideal selection when there is a need for both robustness and flexibility. By fusing metal with filler material within the composite structure, these gaskets deliver consistent functionality across varied environments. They are adept at creating tight seals and preventing any leaks. This includes those designed from solid material elements.

Key Factors in Gasket Selection

Selecting the appropriate gasket materials is vital for maintaining the durability and performance of mechanical assemblies. These materials are designed to fill in any spaces between two joining surfaces, ensuring a tight seal that prevents leakage under compression. For effective sealing, it’s important to take into account factors such as resistance to chemicals, temperature ranges, pressure levels, and other physical forces.

Internal pressure contributes significantly to the effective sealing, particularly in spiral wound gaskets, which utilize internal pressure to ensure a tight seal against the flange faces.

The behavior of gasket materials can be significantly altered by environmental conditions which may affect their efficacy when put into use. Choosing unsuitable gasket materials could lead to delays in projects and incur increased expenses. Hence, comprehending these essential elements is indispensable for making well-informed choices.

Subsequent sections will provide an in-depth exploration of how temperature and pressure considerations along with exposure to various media and broader environmental influences play pivotal roles in selecting gasket material options.

Temperature and Pressure

The durability of gaskets is markedly affected by the operational temperatures and pressures to which they are exposed. High pressure can cause lasting changes in gasket shape, thus undermining their capacity to seal properly. The everyday operating conditions involving temperature and pressure take precedence over peak ratings since the endurance of gaskets under regular usage is crucial.

Achieving sufficient gasket seating stress during installation is essential to create a reliable seal and to minimize the risk of leakage in service.

Metallic gaskets stand out for their robustness and ability to endure harsh environments, making them ideal choices for systems that involve high-pressure steam among other demanding applications. Through vigilant inspection routines and selecting appropriate materials, challenges such as creep relaxation can be countered effectively, thereby preserving the efficiency of the sealing function as time progresses.

When crafting a design for a gasket, engineers specializing in this area diligently assess particular needs pertinent to its application with an aim to advise on optimal material selection and configurations that align with achieving top performance standards.

Media Exposure

It is essential to select a gasket material that can withstand particular environmental conditions in order to avoid quick deterioration and malfunction. When exposed to different fluids and chemicals, chemical reactions may occur which could weaken the integrity of the gasket.

By choosing materials that are compatible with the fluids they will come into contact with, you can ensure both longevity and effective performance of the gaskets.

Environmental Considerations

Exposure to excessive heat or cold, dampness, and chemicals can greatly reduce the longevity of a gasket. Degradation of materials is often caused by ultraviolet rays and ozone. Thus it’s crucial to choose appropriate materials based on the surroundings.

The responsibility for choosing materials that will withstand particular environmental factors and fulfill operational needs lies heavily with gasket design engineers. They are essential in ensuring material suitability for these specific conditions.

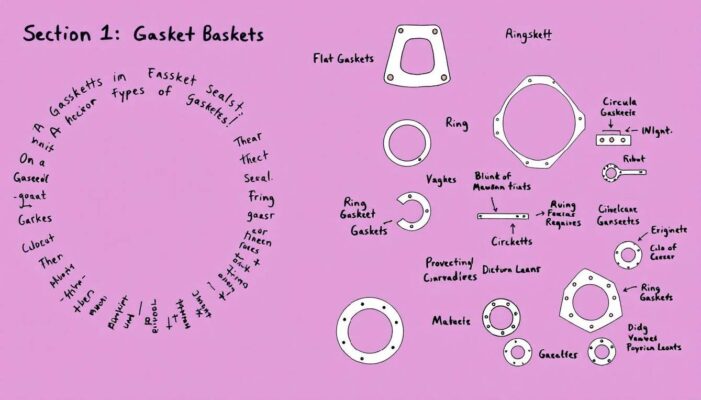

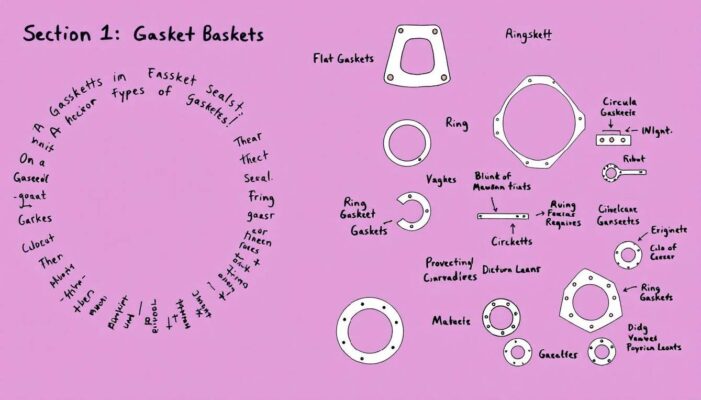

Types of Gaskets and Their Applications

Gaskets serve a multitude of purposes across diverse sectors. Their application is seen in industries such as:

- Oil and gas

- Pulp and paper

- Electric generation

- Transportation

- Food processing

- Petrochemicals

- Plumbing

- Machinery

- Gas applications

This demonstrates their adaptability. In the food and pharmaceutical sectors, sanitary sealing solutions play a critical role by maintaining hygiene standards and safeguarding against contamination.

Other metal gasket systems, such as ring joints, utilize the metal’s own spring characteristics for sealing, which is particularly relevant in high-pressure applications.

In automotive parts and industrial machinery like pumps and valves, rubber gaskets are particularly valuable due to their pliability and durability. EPDM rubber gaskets boast an extensive usage spectrum that includes car components, medical apparatuses, building projects, as well as electronic devices.

Subsequently, we will delve into specific varieties of gaskets along with detailed descriptions of their respective roles in various domains.

Spiral Wound Gaskets

Comprised of a V-shaped metal strip intertwined with a softer filler material, spiral wound gaskets are engineered to offer reliable sealing in environments subjected to high temperatures and pressures. The integration of both metallic strength and the flexibility of the filler allows these gaskets to adeptly respond to varying conditions.

Traditional gaskets experience maximum compression and stress at the outer gasket edge when the flange fasteners are tightened, leading to a potential failure point.

Due to their robustness and ability to preserve an efficient seal even under strenuous circumstances, spiral wound gaskets have become indispensable for applications involving intense pressure. Their performance has made them a favored option across numerous industrial settings.

Double Jacketed Gaskets

Double jacketed gaskets are designed with a softer sealing material at their core, which is enveloped by two robust metal layers. This structure offers superior durability and the ability to withstand high pressure. These gaskets excel within high-pressure steam systems due to their capability of enduring rigorous conditions while still maintaining an effective seal.

These gaskets’ unique makeup enables them to preserve both their structural integrity and sealing capacity, even in severe service conditions. They are particularly suited for challenging environments where they must resist elevated pressures and temperatures, thereby guaranteeing consistent reliability and functionality.

Constant Seating Stress Gaskets

Constant seating stress gaskets are engineered to exert uniform compression throughout their entire surface, effectively averting the occurrence of leaks. Their design assures that the constant seating stress gasket provides a steadfast seal even when operational conditions fluctuate.

Constant seating stress gaskets maintain a uniform gasket seating stress across the sealing area by accounting for flange rotation and deflection under bolt preload.

Such gaskets are exceptionally beneficial in situations where preserving consistent pressure is essential for leak prevention and system reliability. They offer adaptability to variations in pressure and temperature, establishing them as a reliable option for numerous industrial uses, particularly when addressing issues with service leakage and flange gasket applications.

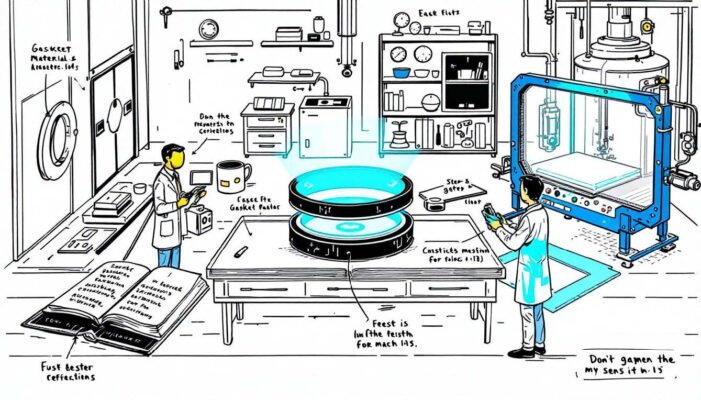

Testing and Certification of Gaskets

Confirming the dependability and functional efficacy of gasket materials in diverse applications necessitates rigorous testing and certification. Such regular evaluation is imperative to maintain conformity with quality benchmarks and to pinpoint potential defects prior to their introduction into the marketplace. This stringent vetting process is instrumental in upholding both the integrity and trustworthiness of gaskets, thereby preventing malfunctions when they are utilized.

Possessing an ISO 9001:2015 certification reflects an entity’s dedication to superior management practices that promote not only heightened productivity but also increased client satisfaction. Subsequent segments will explore distinct methodologies for testing as well as various endorsements related to these processes.

Hot Compression Test

A hot compression test assesses the capacity of a gasket material to withstand elevated temperatures and compressive forces. It establishes the maximum temperature the material can tolerate without sustaining harm, confirming its ability to preserve sealing integrity during actual use conditions.

ISO 9001:2015 Certification

The attainment of ISO 9001:2015 certification signifies an organization’s dedication to upholding stringent quality management protocols, thereby boosting operational efficiency and amplifying customer satisfaction. Mercer Gasket is one such certified entity that adheres to these rigorous standards, guaranteeing uniformity throughout its production procedures.

Regulatory Standards

Organizations that regulate industry standards, such as Underwriters Laboratories, define safety benchmarks for gaskets. They ensure these products adhere to essential performance and safety requirements necessary for their reliable and safe utilization in commercial applications.

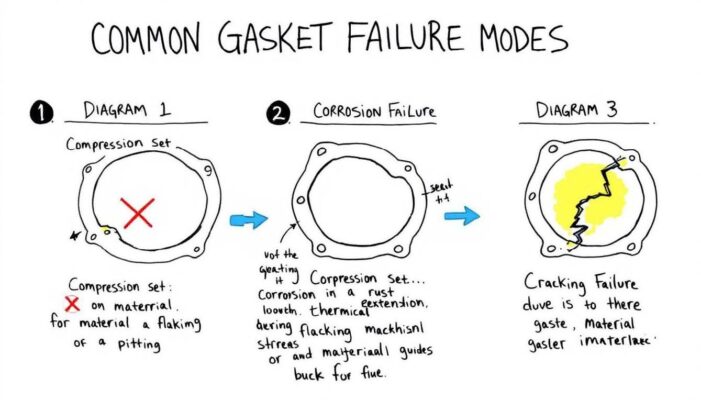

Common Gasket Failure Modes

Choosing the right gasket material is essential to prevent leaks and equipment malfunctions, which can result in expensive repairs and operational downtime. Familiarity with common gasket failure modes, such as creep relaxation, disproportionate pressing force distribution, and material deterioration, is critical for their prevention and for maintaining optimal gasket performance.

If the flange sealing surfaces are capable of attaining a seal, the sealing elements are compatible with the process fluid, and a sufficient gasket seating stress is established during installation, then the likelihood of the gasket leaking in service is significantly minimized or eliminated.

Creep relaxation happens when a material gradually deforms and its ability to maintain sealing pressure diminishes over time under continuous load. When an uneven force is applied during fitting, it can lead to incomplete seals and concentrated stress points that may cause the gasket to fail prematurely.

Degradation of the gasket material can occur if it comes into contact with media or environmental conditions that are not compatible with it. This exposure leads to a reduction in its ability to effectively seal.

Creep Relaxation

Creep relaxation describes the gradual deformation of materials that occurs when they are subject to unvarying stress, ultimately diminishing their ability to maintain a seal. The significance of choosing materials resistant to sustained stress lies in preventing deformations that can result in a reduction of sealing efficacy. This process may be responsible for persistent leaks or severe blowouts due to imbalanced pressure distribution and the natural weakening of material under stress.

To combat the effects of creep relaxation, it is essential to select gaskets crafted from substances known for their minimal creep tendencies. Consistent inspection and upkeep play pivotal roles in spotting early indicators of this condition, thus enabling prompt actions aimed at averting potential failures associated with gasket seals.

Uneven Distributed Pressing Force

Applying force inconsistently during the setup process can result in incomplete sealing and concentrated stress areas, which may cause a gasket to fail prematurely. If the applied pressure is not uniform across the sealing surfaces, it heightens the potential for leakage and compromises the integrity of the gasket due to increased stress concentrations. Factors that could lead to this uneven distribution include incorrect installation practices or substandard flange fasteners.

To mitigate against such failures, it’s crucial to ensure a consistent application of pressing force throughout both the gasket surface and around all flange sealing surfaces as part of leakage prevention measures. This consistent application is essential to prevent leakage during operation. Achieving this requires adherence to correct installation protocols along with using suitable tools and methods designed for this purpose.

Conducting routine checks and upkeep procedures aids in detecting any existing problems with non-uniform pressing forces early on so they can be addressed swiftly before resulting in more significant issues.

Material Degradation

Selecting appropriate gasket materials is essential to avoid deterioration and guarantee the best performance during use. Choosing a gasket material that doesn’t align with the media it will come into contact with often results in early failures and a decrease in its ability to maintain a seal. Various fluids may trigger chemical reactions which can lead to weakening of the gaskets, causing them to degrade and possibly leak.

Sheet gaskets involve acids and other aggressive media, highlighting the importance of selecting the right material for gaskets used in environments where exposure to these substances is a concern.

The integrity of the seal can be undermined by degradation of gasket material, leading to increased costs for maintenance as well as downtime affecting operations. It’s crucial to opt for materials capable of resisting specific chemicals and environmental conditions they’ll face, preventing material breakdown and securing sustained efficacy in gasket performance.

Consulting with Experts

Seeking guidance from specialists is crucial when choosing suitable gasket materials and designs. Converters with experience can navigate you through the enhancement of your design and the choice of appropriate materials, making certain that your gasket fulfills its particular functional needs. Engineers who specialize in gasket design offer customized recommendations regarding material options, aiding in decisions that boost both the performance and dependability of the gasket.

Solid material gaskets are high-quality gaskets made from metals that cannot be punched out and can withstand extreme temperatures and pressures.

Similarly critical is the selection of an adept supplier. Suppliers with a wealth of experience have insights into industry trends and distinct requirements which markedly improve the efficacy of a gasket. Those suppliers who grasp subtle industry distinctions contribute to superior gasket functionality and durability, thereby guaranteeing success for its intended application.

Role of Gasket Design Engineers

Expert gasket design engineers play a crucial role in choosing the appropriate materials and designs for given applications. Their specialized knowledge is key to ensuring that the selected gasket materials and configurations conform to operational needs, thereby mitigating typical modes of gasket failure and improving general performance.

Choosing the Right Supplier

Selecting gasket suppliers with a wealth of experience guarantees the proper selection of gaskets for particular uses. These adept suppliers offer valuable expertise about unique industry demands that affect the choice of gaskets, resulting in enhanced performance and extended life for these components.

Summary

Selecting the appropriate gasket material is an essential step that greatly influences both effectiveness and durability within mechanical assemblies. It’s crucial to comprehend various gasket materials, their specific uses, and the pivotal elements that affect how they perform. Each kind of material—be it rubber, metal or composite—carries its own set of advantages tailored for distinct operational circumstances.

Taking into account aspects such as pressure levels, temperature ranges, media contact and ambient conditions is key when choosing a suitable gasket material for your particular requirements. Ensuring regular testing and certification can confirm compliance with industry benchmarks and consistent performance reliability. Working with experts in selecting a reputable supplier can Improve both the dependability and functioning of your gaskets.

Adhering to this detailed guide’s advice allows you to steer clear of typical reasons behind gasket failures while maximizing your mechanical systems’ efficiency. The correct choice in a gasket plays an instrumental role not only in averting leaks but also in diminishing service expenses, contributing to uninterrupted operations throughout your facilities.

Frequently Asked Questions

What is a gasket slang?

A gasket in slang refers to someone becoming very angry or upset.

For example, “Jack blew a gasket” indicates he reacted with intense anger.

How do you choose the right gasket material?

To choose the right gasket material, assess your application requirements considering factors such as temperature, environment, industry standards, compression set, and durometer.

This methodical approach ensures the gasket will perform effectively in its intended use.

What types of gasket materials are mentioned in the text?

The types of gasket materials mentioned include rubber, metal, and composite gaskets, specifically Neoprene, EPDM, and spiral wound gaskets.

Why is it important to choose the right gasket material?

Choosing the right gasket material is essential as it directly affects the gasket’s performance and durability, helping to prevent leaks and maintain system efficiency.

This decision can ultimately save time and costs related to repairs and maintenance.

What is a common application for double jacketed gaskets?

Double jacketed gaskets are commonly used in high-pressure steam systems due to their ability to endure extreme conditions while ensuring a reliable seal.