Fasteners

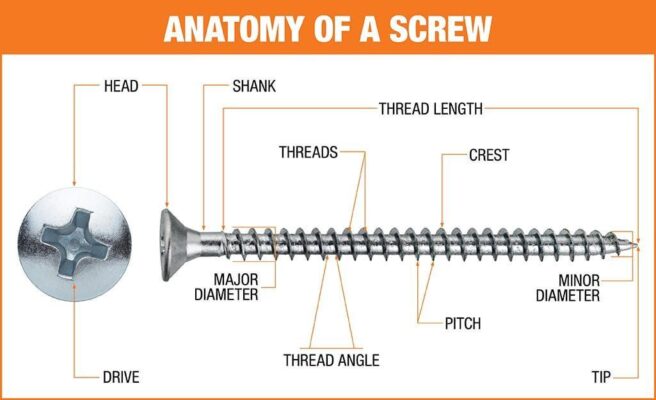

Anatomy of a Screw

Anatomy of a Screw: Key Components and Materials Explained

When it comes to choosing the right screw for a task, understanding the anatomy of a screw is essential. In this article, we’ll break down the key components of a screw – the head, shank, threads, drive, and tip – and how each part influences its performance in different applications. Additionally, understanding screw anatomy is crucial for optimizing manufacturing processes.

Key Takeaways

- Screws consist of key components including the head, shank, threads, drive, and tip, each contributing to their overall performance and suitability for various applications.

- Materials like steel, stainless steel, and specialty alloys are commonly used to enhance screw strength, durability, and corrosion resistance, with coatings further improving performance in harsh environments.

- Accurate measurement and classification of screws are critical for ensuring compatibility and functionality across diverse applications, influenced by international standards such as ISO metric and UTS.

- Understanding screws alongside other fasteners is essential for comprehensive hardware knowledge, ensuring a versatile assortment for various applications in workshops and maintenance tasks.

What is a Screw?

A screw is a versatile type of fastener designed to hold objects together by being inserted into a pre-drilled hole and turned to create a secure connection. Essentially, it is a simple machine of the inclined plane type, consisting of a spirally grooved solid cylinder and a correspondingly grooved hollow cylinder into which it fits. This unique design allows screws to convert rotational force into linear motion, making them incredibly effective at securing materials.

Screws are distinguished by their helical ridge, known as the thread, which wraps around the shank. This thread engages with the material, providing grip and mechanical advantage. The head of the screw, which can come in various shapes such as flat, round, or hexagonal, is designed to be driven by a tool, such as a screwdriver or wrench.

The versatility of screws makes them indispensable in a wide range of applications, from construction and woodworking to electronics and machinery. Whether you’re fastening wood, metal, or plastic, choosing the right screw ensures a strong and reliable connection.

Essential Parts of a Screw

Screws are more than just bits of metal; they are intricate devices with several key components, each serving a unique function. Knowing these components helps in choosing the right wood screw for your needs, so you won’t feel screwed when making your selection.

The primary parts of a screw include the head, shank, threads, drive, and tip. Each part affects the screw’s performance and suitability for different tasks. Some screws, particularly those used in manufacturing, feature a blunt end rather than a pointed tip, which is more common in applications involving pre-tapped holes.

Head

The screw head is the topmost part, designed to transfer the twisting force from a tool to the screw itself. There are two primary categories: countersunk and non-countersunk. Countersunk heads sit flush with the surface for a smooth finish, whereas non-countersunk heads protrude above the surface.

Common head shapes include hex heads, often used in heavy-duty applications like lag screws, and breakaway heads, which prevent tampering after installation. Lag screws often come with hex or square heads, requiring specific tools for installation.

Shank

The body of the screw is composed of the shank, which extends from the head down to the point and plays a crucial role in defining the screw’s load capacity. Variations in its length and diameter are tailored to meet diverse strength requirements for various applications. Certain screws feature segments on their shanks that lack threads, which are intentionally crafted for specialized fastening purposes.

In concert with both its point and threads, it is this shank that constitutes the integral structure of a screw’s body.

Threads

The shank of a screw is encircled by ridges known as threads, which facilitate its rotation and provide grip. These helical structures grant mechanical leverage that aids in tightening the screw and securing it in position.

In the United States, thread specifications are dictated by the Unified Thread Standard (UTS), which encompasses commonly used series such as UNC, UNF, and 8-UN. The spacing between crests varies: coarse threads have larger intervals whereas fine threads feature narrower ones—this difference influences how they behave when subjected to loads.

Drive

The section of the screw where a tool engages to rotate and secure it in place is known as the drive. Various drives like slotted, Phillips, and hex demand distinct tools such as wrenches or screwdrivers for their specific shapes. Socket heads are a common feature in machine screws, enhancing usability and connection strength.

How effortlessly a screw can be installed and how effectively torque can be applied is significantly influenced by the type of drive utilized.

Tip

The tip of the screw begins engagement with the material to be secured. Screws designed for wood often feature pointed tips that can easily penetrate wood fibers. In materials such as wood or plastic, self-tapping tips are employed to form their own threads, simplifying the installation process.

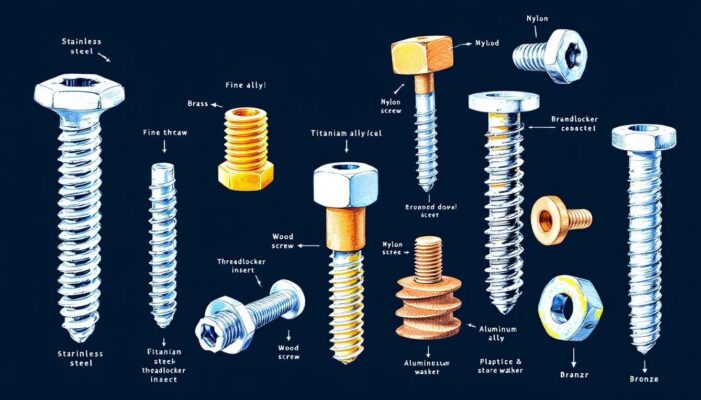

Materials Used in Screws

Screws are manufactured from a diverse range of materials, chosen based on their unique characteristics and the requirements of particular uses. The primary form of material utilized in screw production is either wire or round bar stock. To boost the longevity and functionality of screws under various environmental circumstances, coatings are often applied. Pins are also a common type of fastener used in various applications, highlighting the variety of fastening solutions available.

For environments that present challenging conditions, such as those prone to corrosion, screws are meticulously crafted with these considerations in mind to ensure they can withstand harsh elements.

Common Materials

Screws are most commonly made from steel, which comes in different grades influencing their strength and resistance to corrosion. Stainless steel screws, known for their superior corrosion resistance, are particularly suitable for use in outdoor and marine settings.

Although it is possible to manufacture screws from plastic and rubber, the more frequent choice is either steel or stainless steel because of their robustness and long-lasting durability.

Specialty Materials

Copper is renowned for its ability to resist corrosion, which makes it perfectly suited for situations where corrosion is a concern. Bronze alloys are crafted to boost both the durability and resistance to corrosion, attributes that make them highly valuable in marine applications.

Incorporating specialty materials such as copper and particular alloys into screws can significantly improve their performance and extend their service life across diverse uses.

Screw Finishes and Coatings

Coatings and finishes play an essential role in enhancing the durability and performance of screws. These treatments help shield screws from wear and corrosion, thus ensuring they remain effective across diverse environmental conditions.

Protective Finishes

Protective finishes are essential for screws used in harsh weather or chemical environments. Zinc plating is popular for its corrosion resistance, especially in humid conditions. Hot dip galvanization provides a thicker zinc layer, offering superior corrosion resistance.

Chromium coatings protect screws from wear, creating a tougher and easy-to-clean surface.

Aesthetic Finishes

Aesthetic finishes enhance the visual appeal of screws, making them ideal for decorative applications. Antique brass finishes lend a vintage look, while bright brass finishes provide a shiny and attractive appearance.

Nickel plating enhances both corrosion resistance and aesthetic appeal, making it a popular choice for visible installations.

Measuring and Classifying Screws

Ensuring precise measurement and categorization is essential to achieve the correct fit, durability, and dependability across different uses.

The classification of screws into internal and external drives determines which installation tools are necessary.

Measurement Terminology

Understanding measurement terms is key to choosing the appropriate screw. The major diameter, incorporating the thread’s height, is an essential dimension to consider.

Accurate measurements ensure that the chosen components will be compatible and function correctly.

Classification Standards

The ISO metric screw thread is the global standard, ensuring compatibility across various projects. In the US, the Unified Thread Standard is common, with inch-based measurements used in about 60% of screws.

UTS screws are described by their nominal size and threads per inch.

Applications and Uses of Screws

Screws play a critical role across numerous industries, including aerospace, electronics, automotive, and construction. They are indispensable for ensuring both stability and functionality. Their application is widespread, ranging from fastening elements in building projects to the intricate assembly of small-scale electronic gadgets.

Industrial Applications

In industrial settings, stainless steel screws are favored for their rust resistance and structural integrity. Brass screws are favored in marine applications due to their durability in salty environments.

Machine screws fit into pre-threaded holes in machinery and electronic devices.

Consumer Applications

During home improvement projects, screws are frequently employed for the convenient assembly of furniture and fixtures. Screws made from plastic are particularly appreciated for their corrosion resistance and light weight, making them suitable in scenarios where metal fasteners or other types might lead to electrical interference.

In decorative applications where visual appeal is important, brass screws are preferred due to their attractive appearance.

Custom Screws

Screws that have been customized are crafted to cater to specialized needs, tackling distinctive obstacles encountered in diverse applications. They can be fine-tuned regarding their dimensions, the materials they’re composed of, and the design of their thread patterns so as to fulfill particular specifications for a project. The importance of manufacturing processes in producing custom screws to specific requirements cannot be overstated, as it ensures efficiency and precision in meeting these unique demands.

These specialty screws may be constructed with tamper-resistant features to enhance security within their intended application.

Summary

Understanding the anatomy of a screw is essential for selecting the right type for your projects. From the head to the tip, each component plays a critical role in the screw’s performance. The materials and finishes used in screws enhance their durability and functionality, making them suitable for various applications. Whether you’re working on a home improvement project or a specialized industrial task, knowing the right screw to use can make all the difference. Remember, the right screw can ensure the longevity and stability of your projects. Additionally, understanding the differences between screws and bolts is crucial for selecting the right fastener for your project.

Frequently Asked Questions

What materials are commonly used in screws?

Screws are primarily made from steel and stainless steel, which are chosen for their robustness and ability to withstand corrosion.

What is the purpose of a screw’s finish?

A screw’s finish is designed to safeguard it against wear and corrosion, which in turn boosts its durability and ensures optimal performance across different settings.

What are the main types of screw drives?

There are several principal screw drive types, including slotted, Phillips, and hex. Each type requires the use of particular tools to ensure they are installed correctly.

By becoming familiar with these different types, you can increase your ability to utilize screws more efficiently.

How are screws measured?

Screws are measured by their major diameter, thread pitch, and length, which ensures their compatibility and functionality in various applications.

Accurate measurements are essential for proper installation and performance.

What are custom screws?

Custom screws are specialized fasteners tailored to specific requirements, allowing modifications in size, material, and thread pattern to suit unique project needs.