Fasteners

Common Mistakes to Avoid When Using Fasteners

Must-Know Tips: Common Mistakes to Avoid When Using Fasteners

Mistakes in using fasteners can lead to project failure or safety hazards. In this guide, we’ll highlight common mistakes to avoid when using fasteners, ensuring you achieve reliable and lasting results.

Key Takeaways

- Select the correct fasteners and ensure material compatibility to prevent structural failures and corrosion risks.

- Maintain precise dimensional accuracy and use appropriate tools to avoid damaging fasteners and materials.

- Follow best practices for torque application, pre-drilling, and safety measures to enhance installation quality and project durability.

Incorrect Fastener Selection

Ensuring you select the right fasteners is crucial for maintaining the structural integrity and extending the lifespan of your project. Utilizing fasteners that aren’t adequately sized can have severe consequences, particularly in critical areas such as aerospace or healthcare where safety is of utmost importance. The thought alone of a catastrophic failure due to improper size or type of fasteners is chilling. Using a user-friendly website can help in selecting the correct fasteners efficiently.

It’s equally vital to consider screw length. It’s key to effectively secure materials together while avoiding weak points in construction. Using screws that are too long or too short could lead to irreversible harm being done to the materials involved.

To uphold structural soundness and avert potential safety threats, it’s essential to carefully choose high-quality fasteners that align with the required application dimensions, thereby diminishing chances of mishaps or injuries during their installation process.

Fastener Material Selection and Properties

Choosing the right material for your fasteners is crucial for ensuring the structural integrity and longevity of your project. Different materials offer varying levels of corrosion resistance, strength, and durability, making it essential to match the fastener material to the specific requirements of your application.

Common fastener materials include stainless steel, aluminum, and carbon steel. Stainless steel is known for its excellent corrosion resistance and strength, making it ideal for outdoor and marine applications. Aluminum is lightweight and resistant to corrosion, but it may not offer the same strength as stainless steel. Carbon steel, on the other hand, is strong and cost-effective but requires protective coatings to prevent rust.

When selecting fasteners, consider material properties such as tensile strength, yield strength, and hardness. The American Society for Testing and Materials (ASTM) provides standards for these properties, ensuring that fasteners meet specific performance criteria.

It’s also important to consider the environmental conditions your fasteners will face. Factors like temperature, humidity, and exposure to chemicals can affect the performance and longevity of the fasteners. Ensuring material compatibility between the fasteners and the components they join is essential for optimal performance and durability.

Ignoring Material Compatibility

The selection of fasteners should be heavily influenced by the compatibility of materials. By choosing a fastener that is made from the same material as the components being joined, you can significantly reduce the potential for corrosion. An example of this issue is galvanic corrosion that arises between aluminum and stainless steel, causing considerable deterioration in both substances. Recognizing how different materials interact with one another is essential.

It’s important to take into account concerns such as hydrogen embrittlement—a phenomenon where hydrogen seeps into metal and undermines its structural integrity and pliability. To avoid early breakdowns and guarantee extended durability of projects, always consider whether your fasteners are compatible with their corresponding materials.

Overlooking Dimensional Accuracy

Fasteners require precise dimensional accuracy. A fastener that is off by even a single millimeter can lead to uneven load distribution, loosening, and increased corrosion. Create detailed plans accounting for material thickness and fastener lengths to ensure precise dimensions.

Accurate dimensions ensure fasteners fit correctly, maintaining stability and connection quality. Consistent fastener sizes are crucial for compatibility and replacement, maintaining project integrity.

Using Inappropriate Tools

Utilizing the wrong tools may harm the fastener as well as the material it secures. Employing a screwdriver head that doesn’t match can lead to thread stripping and destruction of the screw head, which is a mistake that might critically compromise your project’s structural integrity.

Employing unsuitable tools can also result in setbacks and elevated expenses stemming from incorrect fittings and challenges during installation. Considering these potential impacts on performance, it’s crucial to make sure you’re using the appropriate tools for your task.

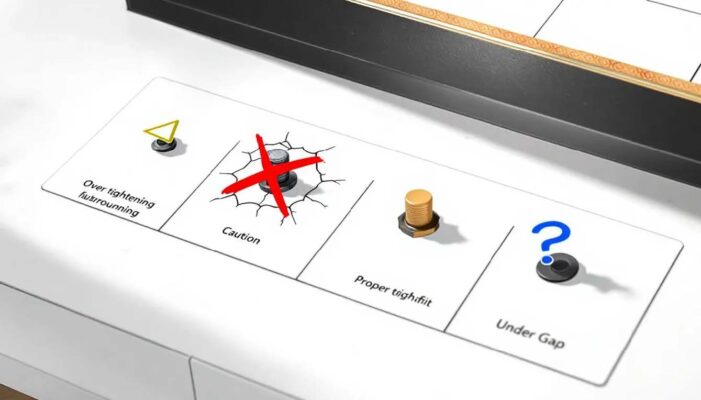

Over-Tightening and Under-Tightening

Over-tightening fasteners can strip the threads, break the screw head, and even crush the material being fastened. Excessive torque can cause structural damage, leading to material breakdown. Conversely, under-tightened fasteners may lose their load-bearing capacity, causing loose connections and safety risks.

Follow manufacturer guidelines on torque values and installation procedures to ensure safety and performance. Correct tools help apply the right amount of torque, preventing over- or under-tightening. This practice ensures the longevity and reliability of your structure.

Not Pre-Drilling Holes

Failing to pre-drill pilot holes before inserting screws into hardwoods may lead to cracking or splitting of the wood, resulting in damage. If you don’t drill beforehand, screws can end up misaligned or cause joints to weaken, which could undermine the overall structural integrity.

By making sure to pre-drill your holes, these problems are avoided and proper fastener installation is assured. Taking this precaution greatly enhances both the quality and longevity of your work, a crucial practice for successful DIY projects.

Misalignment Issues

Misaligned fasteners can cause structural instability, compromising assembly safety. They create stress concentrations that may cause premature component failure. A project collapsing from uneven load distribution due to misalignment can be highly frustrating.

Routine inspections identify misalignment issues early, allowing for corrective actions to prevent failures. Proper fastener alignment maintains mechanical function and material longevity.

Neglecting Environmental Factors

The performance and durability of fasteners are greatly influenced by environmental conditions. Galvanic corrosion can occur when different metals interact in the presence of an electrolyte. Crevice corrosion is a problem that develops in tight spaces where oxygen access is limited.

Fastener materials are subject to expansion or contraction due to extreme temperatures, necessitating periodic adjustments for proper tightness. Over time, exposure to chemicals can wear down fasteners. Selecting materials with strong resistance to corrosion is essential.

Investing in high-quality fasteners diminishes the necessity for maintenance and decreases the need for replacements over an extended period.

Skipping Countersinking

The process of countersinking is designed to enable screws and bolts to integrate seamlessly with the surface, ensuring that the heads of these fasteners lie flush with the material for a sleek, expert finish.

This technique not only streamlines the installation procedure, making it faster and more effective, but also delivers an aesthetically pleasing result while eliminating any potential safety risks associated with protruding screw heads.

Fastener Installation Best Practices

Proper fastener installation is critical for maintaining the structural integrity and longevity of your project. To achieve the best results, always follow the manufacturer’s instructions and adhere to industry standards.

One of the most important aspects of fastener installation is using the correct torque specification. Over-tightening can damage the fastener and the material, while under-tightening can lead to loose connections and potential failure. Using a torque wrench can help ensure that you apply the right amount of force.

Installing fasteners in a clean and dry environment is also essential. Contaminants like dirt and moisture can lead to corrosion and weaken the connection. Additionally, using lubricants and coatings can improve the installation process and enhance the performance of the fasteners.

Regular inspection of installed fasteners is crucial to detect any signs of wear or damage. This practice helps maintain the integrity of the connection and prevents potential failures. By following these best practices, you can avoid common mistakes such as overdriving and stripping, ensuring a successful and durable installation.

Overdriving and Stripping: How to Avoid and Recover

Overdriving and stripping are common mistakes that can occur during fastener installation, leading to compromised connections and potential project failure. Overdriving happens when a fastener is driven with too much force, causing excess pressure that can reduce sealing performance over time. Stripping occurs when the fastener is over-tightened, damaging the threads and making it difficult to achieve a secure hold.

To avoid these issues, it’s essential to use the correct torque specification for your fasteners. A torque wrench can help you apply the right amount of force, preventing overdriving and stripping. Regularly inspecting the fasteners during installation can also help you catch any issues early and make necessary adjustments.

If overdriving or stripping does occur, there are ways to recover. Specialized tools, such as screw extractors, can help remove damaged fasteners. In some cases, it may be necessary to replace the fastener entirely to ensure the structural integrity and longevity of the project. Proper training and experience can significantly reduce the likelihood of these mistakes, leading to more successful installations.

Quality of Tools and Fasteners

Putting resources into top-notch fasteners mitigates the risks of installation problems and promotes enduring project stability. Utilization of inferior tools has the potential to mar screw heads and fray threads.

Utilizing countersinks aids in safeguarding screw heads from harm while being tightened, thereby enhancing their lifespan. Depend on reputable suppliers when acquiring custom products to guarantee that they meet a high standard of quality and performance for your customers.

Custom and Specialty Fasteners

Custom and specialty fasteners are designed to meet specific requirements for unique applications and industries. These fasteners can be made from a variety of materials, including exotic metals and alloys, to provide the necessary strength, corrosion resistance, or other properties needed for specialized uses.

The use of custom and specialty fasteners can offer a competitive advantage in terms of performance and reliability. For example, in the aerospace industry, fasteners must withstand extreme conditions and high stress, making custom solutions essential. Similarly, in the automotive industry, custom fasteners can improve vehicle performance and safety.

Manufacturing custom and specialty fasteners requires specialized expertise and equipment. Techniques such as machining and forging are commonly used to create these fasteners, ensuring they meet precise specifications. By investing in custom and specialty fasteners, businesses can achieve higher performance and reliability in their products, ultimately enhancing their reputation and success.

Safety Measures When Using Fasteners

When handling fasteners, prioritizing safety is crucial. Children on the site are typically required to don personal protective gear such as safety goggles and gloves to shield themselves from potential harm caused by flying debris or accidents involving slips. Additionally, it is important to keep kids away from the work area to ensure their safety.

Before utilizing screws and other types of fasteners, it’s important to check them for any defects or damage that could compromise their integrity. To avoid accidental movements that can lead to mishaps while installing these components, firmly hold workpieces in place using clamps or vices. Maintaining a tidy and well-ordered working area helps diminish risks and facilitates an efficient work process.

Fastener Storage and Organization for Popular Categories

Proper storage and organization of fasteners are crucial for efficient and effective use. Whether you’re dealing with screws, bolts, washers, or other fasteners, having a well-organized storage system can make a significant difference in your workflow.

Popular categories of fasteners, such as screws, bolts, and washers, require specific storage solutions to keep them sorted and easily accessible. For instance, screws can be stored in compartmentalized bins, while bolts and washers might be better suited to labeled drawers or containers. This organization helps reduce errors, improve productivity, and increase customer satisfaction by ensuring that the right fastener is always at hand.

Fastener storage solutions can be customized to meet the needs of various industries and applications. For example, in the automotive industry, custom storage solutions might include magnetic trays for easy access to fasteners during repairs. In contrast, the aerospace industry might rely on precision-labeled containers to keep track of different fastener types and sizes.

Organized fastener storage can also accommodate different materials, sizes, and types of fasteners. Custom storage solutions can be created for specific fastener categories, such as spacers, rivets, and nuts, ensuring that each type of fastener is stored in a way that maximizes efficiency and accessibility.

Optimizing fastener storage and organization is essential for business operations. It ensures that customers can rely on timely and accurate delivery of products, reducing downtime and improving overall efficiency. By investing in proper storage solutions, businesses can enhance their productivity and provide better service to their customers.

Fastener Inspection and Maintenance for Critical Applications

Regular inspection and maintenance of fasteners are essential for critical applications, such as aerospace, automotive, and medical devices. These applications demand the highest levels of safety and reliability, making it crucial to ensure that fasteners are in optimal condition.

Fastener inspection involves checking for damage, wear, and corrosion, which can compromise the structural integrity of a project. This process includes visual inspections, as well as more advanced techniques like ultrasonic testing or X-ray analysis, to detect any hidden issues.

Maintenance of fasteners includes cleaning, lubricating, and replacing them as needed to ensure optimal performance. For instance, in the automotive industry, fasteners might be regularly cleaned and lubricated to prevent rust and ensure smooth operation. In aerospace, fasteners might be replaced at specific intervals to maintain safety standards.

Critical applications require specialized fastener inspection and maintenance procedures to ensure safety and reliability. These procedures are often outlined in industry standards and regulations, which must be strictly followed to avoid any potential risks.

Fastener inspection and maintenance can be performed by trained professionals or through automated systems. Automated systems can provide consistent and accurate inspections, reducing the risk of human error. However, trained professionals are essential for interpreting results and making informed decisions about maintenance and replacements.

Regular inspection and maintenance can help prevent fastener-related mistakes, reducing the risk of accidents and downtime. This proactive approach ensures that fasteners remain in good condition, supporting the overall safety and reliability of the project.

Fastener inspection and maintenance are critical for ensuring the quality and reliability of custom products, such as t-shirts, and other business operations. By maintaining high standards for fastener performance, businesses can ensure that their products meet customer expectations and regulatory requirements, ultimately enhancing their reputation and success.

Fastener Industry Trends and Innovations

The fastener industry is continually evolving, with new trends and innovations emerging to meet the demands of modern applications. Advances in materials science and manufacturing technology have led to the development of new fastener materials and designs, improving performance and durability.

One significant trend is the increasing use of 3D printing and additive manufacturing in the fastener industry. These technologies allow for the creation of complex and customized fasteners with greater precision and efficiency. Additionally, the trend towards miniaturization and lightweighting is driving the development of smaller and lighter fasteners, particularly in industries like aerospace and electronics.

Smart fasteners and sensors are also becoming more widespread, enabling real-time monitoring and maintenance. These innovations can help detect issues early, reducing the risk of failure and improving overall reliability.

Sustainability is another important trend in the fastener industry. The use of recycled materials and biodegradable fasteners is gaining popularity, reducing waste and minimizing environmental impact. As the industry continues to innovate, businesses can expect to see more sustainable and efficient fastener solutions in the future.

Summary

To recapitulate, steering clear of prevalent errors during the use of fasteners can markedly enhance the security, sturdiness, and durability of your undertakings. It’s imperative to choose suitable fasteners and tools while also guaranteeing that they are installed correctly, as every phase is vital for the triumphant completion of your endeavor.

Bear in mind that dedicating time to grasp these elements and adhering to exemplary procedures will yield dividends eventually. Thus, when you begin a new project in future times, consider this advice carefully and proceed with assuredness and meticulousness.

Frequently Asked Questions

Why is countersinking screws important?

Countersinking screws is important for achieving a clean, professional appearance and preventing projecting heads from creating safety hazards.

This practice enhances the overall aesthetics and functionality of your project.

What safety measures should be taken when working with screws?

To ensure safety when working with screws, always wear personal protective equipment, maintain good lighting, and avoid distractions.

These measures are crucial for preventing accidents and injuries.

What is the consequence of misaligning screws?

If screws are not aligned correctly, it can undermine the structural integrity, leading to fragile connections that may fail.

Hence, it is vital to make sure that screws are properly aligned in order to preserve the strength and stability of a structure.

Why is proper screw length important?

Choosing the right screw length is crucial for ensuring a strong and secure connection between materials, preventing issues such as material splitting or inadequate hold.

Proper screw length guarantees the integrity and durability of the assembled product.

How does the quality of the screwdriver or drill bit affect the use of screws?

The caliber of your screwdriver or drill bit is crucial to the performance when working with screws. Using tools of inferior quality can lead to stripped heads and damaged threads on screws, which decreases efficiency and may even undermine the structural soundness of what you’re building.

Consequently, it’s vital to invest in superior-quality tools if you want to ensure the best possible outcomes for your projects.