Fasteners

How to Ensure Fastener Reliability

How to Ensure Fastener Reliability: The Answer is Standards

Ensuring fastener reliability is critical for the safety and integrity of any construction or industrial project. How to ensure fastener reliability? The answer is standards. This article will explore how fastener standards ensure reliability, laying out their importance, the types of standards available, and the role they play in manufacturing and environmental resilience.

Key Takeaways

- Fastener standards, such as ASTM and DIN, are essential for ensuring the safety and reliability of fasteners used in construction and industrial applications.

- Understanding fastener specifications, including materials and manufacturing tolerances, is critical for selecting the appropriate fasteners that can withstand specific environmental conditions and application demands.

- Compliance with industry standards and maintaining a large inventory of quality fasteners enhance construction efficiency, minimize risks of structural failures, and ensure long-term project safety and reliability.

Importance of Fastener Standards

Fasteners play a pivotal role in the structural integrity of buildings and industrial settings. They are critical for maintaining cohesion, emphasising their importance as reliable elements. Consider the potential havoc that would ensue if fastening components within significant constructions like skyscrapers or bridges were to fail. Their function goes beyond simply connecting parts. They are fundamental in safeguarding the stability and dependability of vast structures. Nails, for instance, are versatile fasteners used in various construction applications, from simple picture hanging to complex installations like siding, and are available in various trusted brands.

The choice of an appropriate fastener standard is crucial for any project’s success. Standards provided by organizations such as ASTM aim to ensure that fasteners adhere to rigorous safety and quality measures tailored specifically for various construction and industrial uses. These standards have been thoughtfully devised with precision, ensuring they cater directly to the distinct demands each application requires.

Employing high-quality fasteners is indispensable when it comes to upholding long-term security and functionality in structures. The consequences of using inferior quality fasteners can be disastrous, potentially risking lives while resulting in exorbitant costs related to repairs and legal liabilities. As such, compliance with recognized standards for these vital components isn’t merely advisable—it’s a fundamental obligation inherent in executing any conscientious construction or industry-related endeavor responsibly.

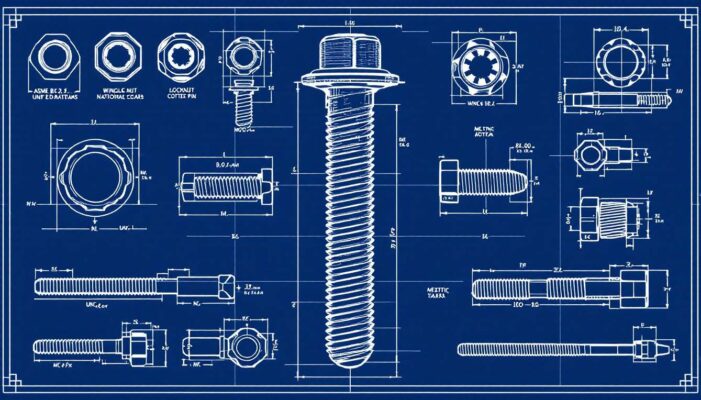

Types of Fastener Standards

The domain of fasteners is subject to a myriad of standards that hold particular significance across different regions and industries. To ensure the selection of an appropriate fastener for a given application, it’s essential to have knowledge about these standards. For example, DIN (Deutsches Institut für Normung) standards from Germany are expansive, encompassing a broad array of fasteners like bolts and screws, with widespread influence in Europe and other areas.

Over in North America, the ASME (American Society of Mechanical Engineers) norms prevail when it comes to specifying criteria for various types such as nuts and bolts. On British soil however, British Standards (British Standards) steer the requirements for diverse categories including screws along with washers.

Crossing over into the Netherlands finds NEN standards guiding regulations for assorted items like nuts and those ubiquitous bolts. While France adheres to NF benchmarks, providing guidelines primarily aimed at products such as screws also incorporating washers.

Regional inclinations aside, these benchmarks play an indispensable role in ensuring safety plus caliber concerning construction-integrated or industry-employed hardware. As manufacturers align their output via adherence to said guidelines, their clients can be secure knowing they receive superior quality pieces which bolster structural integrity globally.

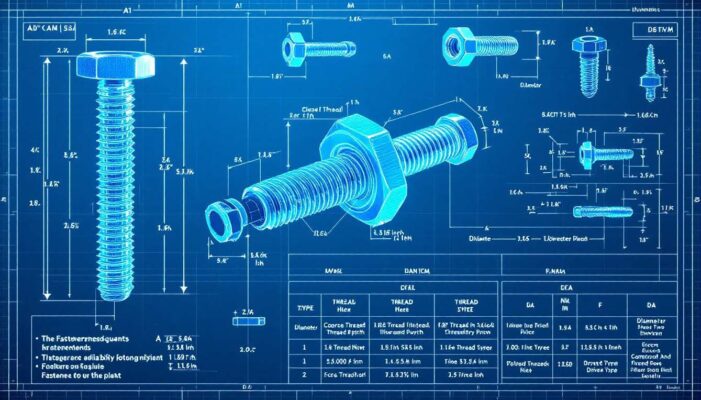

Understanding Fastener Specifications

Understanding the specifications of fasteners is vital to confirm their adequacy for specific applications. Standard-setting bodies such as ASTM and ISO establish essential mechanical properties that fasteners must possess to perform reliably in high-pressure and high-temperature environments. Adherence to these standards enables manufacturers to craft fasteners that conform with safety regulations, especially within critical settings.

The choice of material has a significant impact on the overall quality of a fastener. Materials commonly employed include carbon steel, alloy steel, and stainless steel, each offering varying degrees of strength and resistance against corrosion. Stainless steel variants stand out due to their innate capability not needing extra protective layers while functioning across an extensive range of temperatures—selections like austenitic stainless steel provide heightened resilience against corrosion even under severe conditions.

Enhancing the robustness through heat treatment techniques such as annealing or tempering can render fasteners more appropriate for heavy-duty use. Coatings like cadmium or zinc offer Defense against corrosive agents though they come with inherent temperature thresholds. Post-application baking is mandated to eliminate risks associated with hydrogen embrittlement. Such precise stipulations are indispensable when deciding upon suitable fastening solutions which safeguard persistent dependability and safety over time.

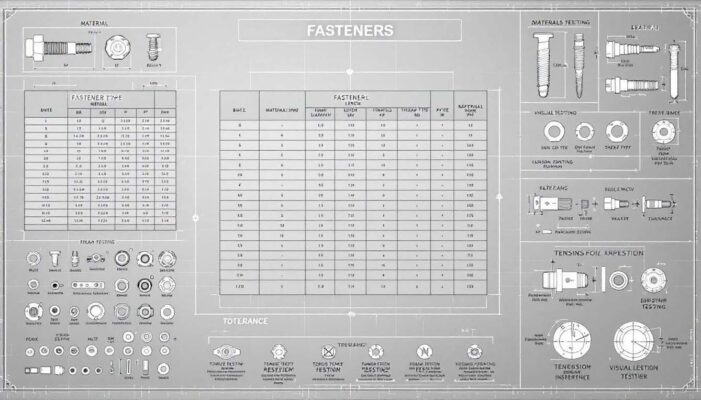

Common Fastener Types and Their Standards

There is a wide array of fasteners tailored for specific roles within construction and industrial tasks. Among these are bolts, screws, nuts, washers, and rivets—all essential in connecting multiple objects together. Typically crafted from metal or plastic among other materials, these elements are instrumental to the durability of constructions when applied as per their intended guidelines.

Bolts manifest in diverse forms such as hex head bolts, carriage bolts, eye bolts, tap bolts and structural bolts each with unique designs catering to particular standards and needs that they must satisfy. Nuts too have various iterations like hex nuts, lock nuts and flange nuts, which pair with corresponding bolt types for tightening purposes. Wing nuts play a crucial role in fastening components together in both commercial and residential applications. Anchoring solutions include adhesive options screw anchors toggle bolt wall anchor drivepin anchors,wedge anchors, solidifying different structures across myriads of contexts.

Adhering to industry benchmarks ensures the effectiveness and security provided by fasteners during usage ist’s vital. Nnot only do these norms dictate manufacturing procedures but also affirm that the Fastener can endure pre-established demands. Tthis dedication upholds the robustness of the machinerybuilding reliant on them.

The Role of Manufacturing in Fastener Quality

The manufacturing accuracy involved in producing fasteners is a substantial factor that affects their quality. Enhanced precision inthe production process ensures better alignment and stronger connections, ultimately elevating product performance. For instance, the reliability of a fastener can be directly linked to its manufacturing tolerances. Typically, tighter tolerances equate to more reliable fasteners.

Nevertheless, attaining high levels of precision entails higher costs. Fabricating fasteners with acceptable tolerance ranges like.499” to.501” is less expensive compared to consistently achieving an exact diameter of.500”. This cost difference is vital for manufacturers since it influences the final price tag on these components. Henceforth, there’s an essential balance that must be struck between precision and affordability when creating quality fasteners.

Adhering to set industry standards during production guarantees that these components comply with required specifications and perform reliably upon use. Quality fasteners crafted meticulously not only reinforce safety and dependability within structures, but also contribute positively to both economic efficiency and effectiveness in various construction endeavors as well as industrial operations.

Environmental Impact on Fastener Lifespan

The lifespan of fasteners is considerably influenced by environmental conditions. Factors like temperature and humidity can lead to complications, including stress corrosion or hydrogen embrittlement, undermining the stability of these hardware components. In environments with high levels of humidity and corrosive substances, fasteners may experience a significantly reduced service life.

In particular, coastal regions are challenging due to their elevated salt content in the air. The presence of saltwater can expedite the rusting process. It’s crucial to employ either coated fasteners or those made from materials resistant to corrosion when operating in such locales. For instance, galvanization offers effective protection for steel fasteners against decay by acting as a sacrificed barrier.

Conducting routine checks in damp settings is critical for identifying premature signs of deterioration or rust on hardware elements like machine screws and bolts. Speaking of fixtures, these fixtures tend to endure longer where they face less climatic strain—for example, on an Iowa farm versus metropolitan areas like Los Angeles that struggle with higher levels of smog and saline mist along with frequent exposure affecting mechanical fittings.

Recognizing how various climates affect metal parts allows us not only to choose suitable types, but also adopt appropriate maintenance procedures aimed at extending their functional span.

Ensuring Compliance with Standards

Adherence to industry standards is crucial for sustaining the structural integrity and ensuring safety. Fasteners of high quality are subjected to rigorous testing processes in order to adhere to these critical standards, which is indispensable for upholding the structure’s integrity. The utilization of fasteners that align with industry benchmarks is vital for guaranteeing both product safety and adherence to legal requirements.

Implementing a Quality Management System (QMS) secures consistent conformity by introducing standardized inspection methods. Comprehensive traceability records are imperative during regulatory examinations since they confirm that the fasteners applied within a project meet all necessary guidelines and laws.

Trustworthy suppliers of quality fasteners typically furnish the requisite documentation validating their compliance with pertinent norms. This verification safeguards projects against potential failures or legal issues by assuring their reliability, security, and lawful legitimacy.

Making Connections with Quality Fasteners

Employing standardized fasteners in construction projects can notably improve the uniformity and dependability of joint connections. By utilizing these consistent components, the potential for structural failures due to incompatible parts is decreased, thereby enhancing safety measures throughout the project.

Tools like Fastenal’s guides offer essential guidance on refining fastening techniques to bolster overall building quality. Having a considerable inventory of such standardized fasteners facilitates expedited completion times and minimizes hold-ups during production phases. Employing quality fasteners ensures that connections remain robust and stand the test of time.

Large Inventory and Selection

Maintaining an extensive selection of fasteners across different materials and dimensions ensures you can always locate the appropriate item for any specific requirement. Conveniently, fastener assortment kits including pin, rivet, screw, and socket varieties offer a broad range of options readily at your disposal. Renowned manufacturers such as Diamond, Lenox, Morse, and Oldham are celebrated for their high-quality fasteners.

Possessing a substantial inventory contributes to accelerated project completion times and reduces potential hold-ups in production. This aspect is crucial within major construction endeavors or industrial operations where efficiently managing time equates to saving money. Having access to an all-encompassing variety of fasteners aids in maintaining continuous workflow throughout projects without disruptions.

Summary

To sum up, the significance of adhering to fastener standards is critical. They play a key role in promoting safety and dependability while also improving efficiency and diminishing expenses across construction or industrial projects. Being knowledgeable about the various classes of fastener standards, their specifications, and how environmental influences affect them is crucial for choosing appropriate quality fasteners for specific tasks.

Quality fasteners serve as the fundamental support system for any building. Ensuring that they are in line with industry norms secures both the durability and structural integrity of your ventures. Commitment to high-quality adherence to established regulations allows you to erect enduring structures that withstand time’s challenges while fostering a safer, more dependable environment globally.

Frequently Asked Questions

What is the ASME standard for fasteners?

The design, dimensions, materials, and testing of fasteners are governed by the standards set forth in the ASME B18 series. Of particular importance to engineers and procurement specialists working within manufacturing and construction fields is ASME B18.2.1.

What are the rules to follow when choosing fasteners?

When choosing fasteners, it is essential to assess the purpose and functionality, environmental conditions, fastener type, material, coating, drive type, size, and compatibility.

Following these guidelines will ensure effective and reliable fastening for your application.

Why is choosing the right standard of fastener important?

Choosing the right standard of fastener is essential for ensuring the safety and reliability of the structure. A proper selection prevents potential failures and contributes to the overall integrity of the construction.

What are fasteners essential for?

Securely connecting components to maintain structural integrity and reliability across a wide range of applications, fasteners are an essential element.

What organizations are involved in creating fastener standards?

ASTM and SME are key organizations in the development of fastener standards, with ASTM focusing on strength specifications and SME addressing sizes and dimensions.