Inventory management

Optimising Your Stock: Top Inventory Management Strategies for Modern Businesses

Aspire to master inventory management? Utilise the power of efficient inventory oversight to reduce expenses, prevent unnecessary waste, and please your customers. How much inventory? This piece provides guidance on optimal practices in managing stock levels, including effective stocking methods and sophisticated software tools, so that your business remains resilient amidst market fluctuations.

Overall Guidelines

- Effective inventory management is essential for operational success, enhancing cash flow and customer satisfaction while minimising costs associated with excess inventory and warehouse space.

- Management techniques such as perpetual inventory systems, Just-in-Time delivery, and Economic Order Quantity help businesses streamline operations, reduce waste, and maintain optimal order quantities to fulfil market demand.

- Advanced tools like inventory management softwares, warehouse management systems, and POS systems provide real-time data and automation to optimise inventory handling and decision-making across the supply chain and your factory system.

Understanding Inventory Management

Every successful business fundamentally depends on the proficient handling of its inventory. This essential management system of your company purchases and stock significantly influences aspects such as cash flow and customer satisfaction, thereby becoming a key component for achieving operational excellence in your business operations. The adept coordination between available stocks of raw materials and finished products provided by an effective inventory management process is crucial in meeting the needs of the market.

In our exploration, we will delve into how the management of materials and goods goes beyond being merely part of organisational workings. It’s actually a catalyst propelling business triumphs.

Defining Inventory Management

Managing inventory involves the meticulous balancing of stock, be it finished products for sale, raw materials for production or items that are currently being processed. This encompasses several essential actions.

- placing orders

- warehousing goods

- consuming supplies

- executing sales

These activities are coordinated via an inventory management system designed to provide instantaneous data on available stock. At its core, this process revolves around comprehensive oversight of the journey taken by each piece of inventory from acquisition to final sale. The goal is to ensure that these materials aid in driving business prosperity instead of causing operational burdens.

The Impact on Business Efficiency

Efficient management of inventory transcends basic organisation. It’s a strategic method to improve business activities. Companies that synchronise their purchasing patterns with real-time demand can reduce the expenses associated with maintaining surplus stock and optimise warehouse utilisation.

Precise prediction methods help to avoid both excessive inventory accumulation and stock shortages, ensuring each dollar spent is geared towards fostering solid cash flow and strengthening the company’s financial health.

Essential Inventory Management Techniques

Within the extensive array of inventory management strategies, several stand out due to their effectiveness in streamlining processes and enhancing productivity. These methods encompass:

- The perpetual inventory system, which offers instantaneous tracking of current inventory levels

- Just-in-Time (JIT) delivery model, which guarantees that inventory is received precisely when required, thereby reducing warehousing expenses

- Economic Order Quantity (EOQ) formula, devised to ascertain the ideal quantity for orders to minimise costs associated with holding stock

Each technique contributes uniquely to improving the intricate operations involved in managing inventories.

Implementing a Perpetual Inventory System

A perpetual inventory system is a fundamental component of contemporary management of inventory, as it constantly refreshes the records with every transaction made—be that a sale or purchase. This method promotes accuracy and substantially reduces the expenses related to labor for manual counting of stock.

Businesses stand to gain from an inventory system aligned closely with their day-to-day activities, thanks to immediate availability of year-end stock balances and reduced costs associated with holding inventories.

Streamlining with Just in Time (JIT)

The Just In Time (JIT) strategy revolutionises the way inventory is managed within a manufacturing context by aligning the arrival of inventory with production schedules, thus minimising the need for extensive storage. By obtaining supplies precisely when necessary for production, factories can maintain minimal levels of stock, which in turn liberates capital and diminishes wastage. Such an approach exemplifies efficient inventory management in contemporary factory settings, demonstrating cost-effectiveness and remarkable flexibility to respond to market demands.

Economic Order Quantity (EOQ) Explained

In the intersection of managing stock purchases and inventory levels, businesses can employ the Economic Order Quantity (EOQ) model. This mathematical formula is designed to identify the optimal quantity for inventory orders by balancing ordering costs with storage expenses. The goal is to minimize these total costs while simultaneously keeping an adequate supply of items on hand to immediately satisfy customer demands.

EOQ takes into account a buffer of safety stock, which provides companies with protection against unforeseen disruptions in their supply chain. Incorporating this safety measure ensures that minor issues do not escalate into major interruptions in operations.

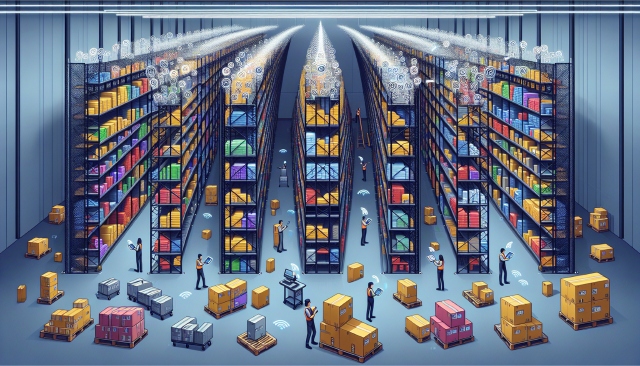

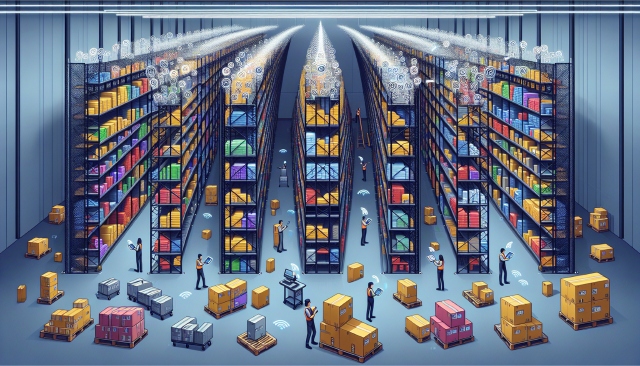

Advanced Tools for Inventory Optimisation

As a company grows and the demand for efficiency intensifies, advanced inventory management software becomes indispensable. Such tools are designed to offer instantaneous data, automate operations, and support decision-making throughout the supply chain. They improve not only the quantity of inventory that a business maintains, but also its ability to adapt swiftly to fluctuations in market conditions—optimizing both warehouse management and overall inventory control.

Leveraging Inventory Management Software

The role of inventory management software is to serve as the core digital structure for contemporary inventory systems, simplifying processes through automation and providing smooth coordination with external logistics services. Notable functionalities of such software include:

- Utilising barcode scanning

- Implementing RFID (Radio-Frequency Identification) technology

- Keeping tabs on inventory levels

- Minimising mistakes made by humans

- Enhancing efficiency in operations

These technologies help to refine the process within factory systems and other related areas, enhancing accuracy in keeping track of inventories while boosting operational productivity. Thanks to immediate data accessibility from varying locations, companies can regulate their stock quantities more effectively and thus secure a stronger position when it comes to managing orders.

Integrating Warehouse Management Systems

A warehouse management system acts as the pivotal hub for storage tactics, optimizing inventory operations across various locations. These systems refine everything from accepting orders to handling labeling, meticulously aligning inventory levels with supply chain needs based on demand.

Incorporating mobile barcode scanners and integration with enterprise resource planning (ERP) tools, these management systems significantly boost the effectiveness throughout the entire span of inventory management in a warehouse.

Utilising POS Systems for Real-Time Data

In the retail industry, inventory management relies heavily on POS systems to provide real-time updates on stock quantities during sales activities. These systems are intricately connected to inventory databases, allowing companies to keep precise counts of their products and facilitate modern shopping conveniences such as ‘buy online, pickup in-store’.

Utilising up-to-the-minute sales information allows businesses to make smart decisions about restocking items efficiently. This ensures that stores remain adequately supplied with goods and helps meet customer expectations for product availability.

Crafting an Effective Inventory Management Plan

Formulating a robust inventory management plan requires:

- A thorough examination of existing processes

- The gathering of relevant data

- Predicting future demand

- Implementing control systems to maintain inventory levels in sync with market dynamics

This strategy is essential for maintaining the efficacy and resilience of a business. The framework not only navigates the complexities inherent in sophisticated supply chains, but also empowers businesses with the ability to quickly respond to shifts in the marketplace, ensuring their agility and competitive edge.

Assessing Supplier Performance and Lead Time

A well-crafted inventory management plan requires assessing the supplier’s performance and timeliness of deliveries. Businesses can employ a balanced scorecard methodology to establish objectives and track key supplier indicators, helping in maintaining optimal inventory levels while controlling expenses.

Having reliable suppliers who provide quick delivery services allows companies to maintain smaller amounts of inventory, which enhances cash flow and improves the effectiveness of restocking procedures.

Balancing Stock Levels and Customer Demand

Managing the equilibrium of inventory with customer demand is essential to prevent stock deficits or surpluses. By utilising strategies such as demand forecasting and applying the reorder point formula, companies can avert having too much or too little inventory, guaranteeing availability of products for customers precisely when required.

Such stability forms the cornerstone of an effective inventory management plan that adeptly caters to customer demands while concurrently managing costs efficiently.

Incorporating Forecasting Models

Inventory management employs forecasting models as key instruments to project future sales, drawing on historical sales data for informed predictions about forthcoming demand. This enables companies to strike a balance in their stock levels, circumventing the risks associated with either excess or insufficient inventory.

Perpetual inventory systems enhance this process by refining forecasts into a finely tuned mechanism that aligns warehouse stock quantities with market fluctuations.

Case Studies: Successful Inventory Strategies

Effective inventory management is validated by its practical implementations, as seen in the success stories of major players such as Amazon, Ikea, and Gap. Their groundbreaking approach to managing inventory encompasses several key strategies.

- Cultivating robust relationships with suppliers

- Setting calculated strategic ordering thresholds

- Leveraging advancements in technology for smoother workflows

- Enhancing efficiency within shipping processes and customer service

When these methods are combined, they result in operations that function without hitches and place a premium on both proficiency and pleasing customers.

S.H. Chooi Fasteners’ Precision Approach

With 40 years of dedicated experience, S.H. Chooi Fasteners has refined its inventory system to the peak of precision through vendor management techniques that bolster quality assurance and optimize stock rotation. Their global renown is built upon a steadfast commitment to delivering impeccably timed fastener supplies.

Their meticulous approach in orchestrating inventory items translates into an efficient supply chain and exemplary supply chain management, which consistently meets customer expectations and cultivates satisfaction.

Abbott Interfast’s Cost-Saving Programs

Abbott Interfast has distinguished itself in the realm of inventory management by offering cost-saving initiatives that deliver a range of benefits, including:

- Adaptability

- Improved productivity

- Minimised levels of inventory stocks

- Decreased need for warehouse storage

- Accelerated frequency of inventory rotation

These solutions, such as Just-In-Time (JIT) and consignment arrangements, are provided to ensure their customers reap these advantages. Such strategies demonstrate how businesses can achieve significant cost reductions while simultaneously upholding superior levels of preparedness with their inventories and delivering exceptional customer service.

Minimising Risks in Inventory Management

Managing inventory comes with its own set of hurdles. Obstacles such as excess inventory, executing orders accurately, and meticulous monitoring pose significant risks to the running of a business. It’s crucial for management to recognise and alleviate these threats in order to prevent expensive complications and disruptions in business activities. Our focus will be on methods for handling surplus stock effectively and maintaining accurate lot traceability—both key elements in reducing risk within the realm of inventory oversight.

Dealing with Excess Inventory

Excessive inventory levels can pose a significant problem for businesses, resulting in economic setbacks due to factors such as deterioration, theft, or changes in consumer demand. To mitigate these risks, companies can adopt various strategies including pairing less sought-after items with bestsellers or providing markdowns on seasonal merchandise to stimulate purchases. Businesses may also cleverly transform perishable stock into promotional incentives to accelerate their sales and simultaneously build customer loyalty.

Ensuring Lot Traceability

In the realm of inventory management, lot traceability acts as a protective mechanism that empowers businesses to monitor components by associating them with a specific lot number. This methodology is critical when complications surface, providing swift pinpointing and facilitating immediate measures such as product recalls or adjustments. Through diligent documentation of inventory lots, companies are equipped to efficiently tackle emerging issues and uphold the robustness of their supply chain.

Adapting to Industry Changes

To stay ahead in the constantly shifting landscape of industry norms and production methods, businesses must adapt their inventory management strategies to retain a competitive advantage. Such an evolution requires:

- Adoption of innovative systems within factories

- Adaptation to the changing dynamics of supply chains

- Maintaining inventory control as a key strategic resource rather than becoming encumbered by it.

The emergence of sophisticated manufacturing processes and advanced factory systems has necessitated the development of inventory management methods that align with more streamlined and complex production processes. Lean manufacturing, which advocates for waste reduction and emphasizes activities that add value, has had a considerable impact on shaping strategies for managing inventory.

Responding to Evolving Supply Chain Dynamics

Disruptions in the supply chain can severely impact both inventory levels and the cost of materials, necessitating that companies implement nimble strategies for managing their inventory. Businesses can utilize cutting-edge technologies such as AI and IoT to obtain valuable insights, enabling them to swiftly adjust their stock quantities or broaden their range of suppliers in response to fluctuations within the supply chain conditions.

How S. H. Chooi can help you with Inventory Management

S.H. Chooi is well-prepared to provide businesses with a range of tailored inventory solutions, including personalised precision fasteners and effective vendor managed inventory systems as well as Kanban programs. These services are designed to enhance the efficiency of inventory management by minimising stock-outs and maximising turnover rates. With competitive ex-works pricing directly from our Penang warehouse, coupled with committed customer service, collaboration with S.H. Chooi represents an important move towards achieving optimal inventory performance.

Seize the opportunity to enhance your business’s inventory management by partnering with S.H. Chooi. Our committed customer service team is on standby, prepared to address your questions, solve any problems you may encounter, and assist you in navigating our array of inventory solutions promptly and proficiently.

You can connect with us via several methods.

- Initiate a live chat

- Fill out a question form

- Send an email to [insert email address]

- Reach out by phone at +604 – 261 3001

Our pledge is to deliver outstanding service and support that meets the high standards your enterprise warrants.

Summary

Businesses navigating the complex terrain of inventory management must arm themselves with a comprehensive strategy that tackles supply chain intricacies, anticipates demand through forecasting, and manages associated risks. The foundational elements for creating an effective and resilient inventory management plan encompass everything from the accuracy achieved by perpetual inventory systems to strategic insights gained via forecasting models. By adopting cutting-edge software solutions, evaluating supplier efficiency, and adjusting to shifts in industry dynamics, your business is poised to overcome conventional barriers and elevate its operational performance to unprecedented levels.

Frequently Asked Questions

What are the benefits of using a perpetual inventory system?

Implementing a perpetual inventory system enhances real-time updates of inventory levels, decreases labor expenses, lessens the likelihood of human mistakes, and heightens the clarity of inventory management. This results in considerable cost reductions and more efficient financial reporting processes.

How can just-in-time (JIT) inventory management be cost-effective?

By minimizing waste, aligning inventory levels with real demand, and reducing the requirement for storage space, JIT (Just-In-Time) inventory management proves to be cost-effective. This strategy liberates capital by ensuring efficient use of resources.

What is Economic Order Quantity (EOQ) and how does it help businesses?

EOQ aids companies in determining the ideal quantity for an order that reduces both ordering and holding expenses while effectively meeting customer demands.

Can inventory management software integrate with other business systems?

Certainly, contemporary inventory management software is designed to synchronize with various business systems in order to enhance the processes related to managing orders and inventory.

What strategies can be used to deal with excess inventory?

Businesses can adopt various tactics to manage surplus stock and align their inventory with consumer demand. These strategies include packaging less popular products together with bestsellers, providing markdowns on goods, converting the merchandise into incentive items, and fine-tuning the amount of inventory held. By implementing these approaches, companies can mitigate issues related to excess inventory while enhancing their sales figures.