Factory Automation

Structural Framing with Aluminium Profiles: Best Practices and Applications

Opting for aluminium profiles in structural framing applications is advantageous due to their notable strength-to-weight ratio, resistance to corrosion, and the simplicity of customisation. This piece provides a detailed examination of optimal methodologies and the various uses for aluminium profiles when engaged in structural framing projects, ensuring you have all necessary information for a well-informed choice. Please note that due to the highly competitive nature of each industry, many counter-arguments have been made. However, we’re here today share key insights about this treasure.

Key Takeaways

- Aluminium profiles are highly valued in various industries due to their high strength-to-weight ratio, resistance to corrosion, and design flexibility, making them ideal for structural framing.

- Different types of aluminium profiles, including SD, RCW, ED, louver, and T-section profiles, are tailored for specific applications such as sliding windows, curtain walls, securing glass, ventilation, and multi-directional support. (Definitions available below)

- The benefits of using aluminium in structural framing include its non-combustible nature, ease of installation and maintenance, potential for frequent reconfiguration, and significant environmental advantages due to its recyclability and energy efficiency in production.

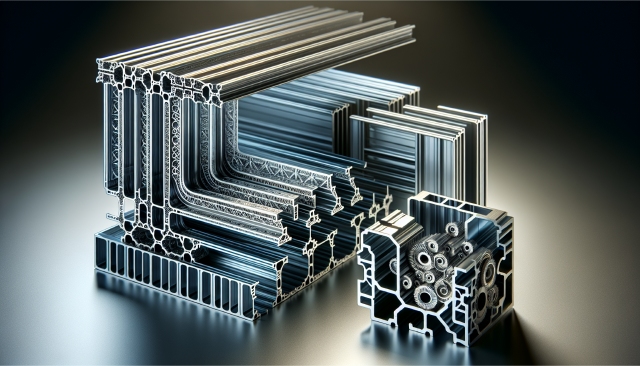

1. Understanding Aluminium Profiles

In the realm of construction and production, aluminium profiles are an often overlooked resource. Employed in a diverse range of undertakings – spanning from contemporary architecture and transportation to machinery for industrial use – these materials bring versatility to myriad applications. Aluminium possesses a distinctive combination of traits associated with both pre- and post-transition metals, which contributes to its impressive strength relative to weight.

Thanks to this special amalgamation of qualities as well as its capacity for light reflection, aluminium stands out as the material par excellence for structural framing purposes within various contexts around the world.

Key Features of Aluminium Profiles

The principal characteristics of aluminium profiles include:

- Durability: Aluminium grades typically used in construction boast a yield strength ranging from 30,000 to 40,000 psi, ensuring strong and resilient components for all types of loading conditions.

- Innovative connection methods: Systems like those provided by Bosch Rexroth have cutting-edge self-aligning connection technologies that simplify designs and reduce the need for multiple parts.

These systems come equipped with secure attachment techniques that guarantee firm and stable framework structures suitable for any location. They cater well to a variety of assets within society. There are the availability of bespoke accessories designed to fit perfectly with these profiles, which facilitates customised solutions and effortless incorporation into existing setups.

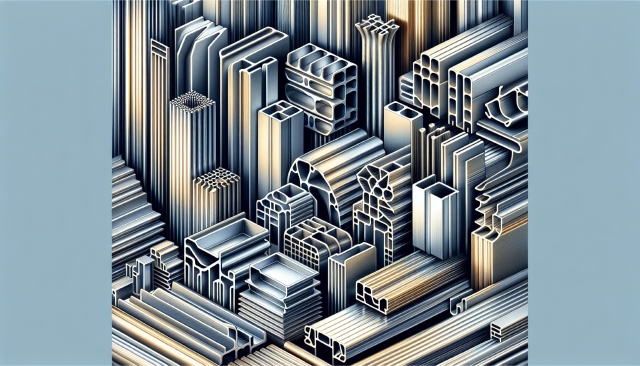

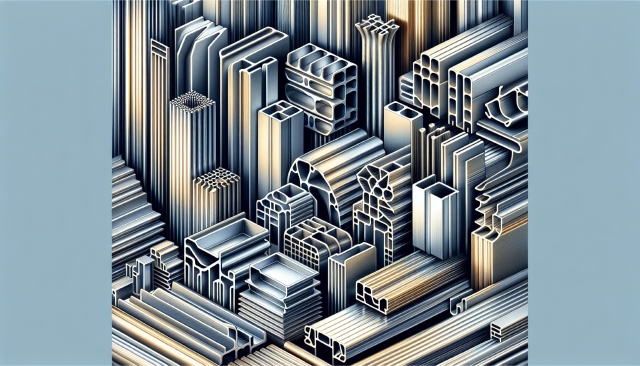

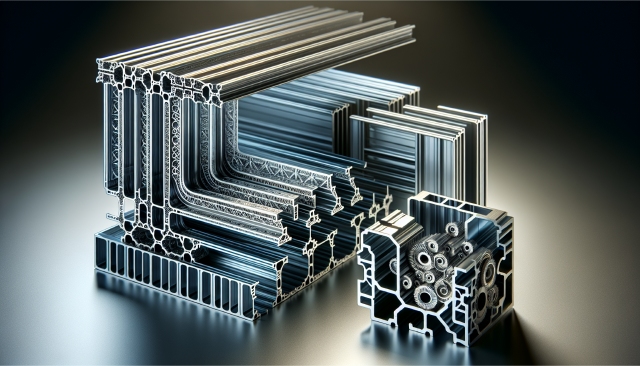

Types of Aluminium Profiles

There exists a diverse array of aluminium profile types, each tailored for particular uses. For example, hollow beam aluminium profiles are often employed in modular setups and serve as horizontal reinforcements within construction designs. The square type of these hollow beams is specifically utilised in wall-bearing structures, acting as support columns and pillars.

Additional forms of aluminium profiles include:

- SD aluminium profiles: selected chiefly for fabricating sliding window frames because they’re light yet strong, adaptable and don’t succumb to corrosion easily.

- RCW profiles: favoured in towering edifices where they function as part of curtain walls or mullions that block out external elements.

- ED sections: integral to the fastening of glass materials within doors found typically in commercial environments

- Louvered versions cater both to permitting daylight entry and facilitating airflow

-T-sections deliver multidirectional reinforcement across various applications.

Benefits of Using Aluminium in Structural Framing

Aluminium profiles possess a range of advantages that render them an ideal option for structural framing purposes, including:

- A high ratio of strength to weight, which allows the construction of structures that are both light and strong

- An inherent non-flammability, which is essential in fire-prone settings

- A resilient nature against corrosion contributes to their lasting performance and minimal maintenance needs

- Their adaptable nature in terms of design and personalisation capabilities (customisation)

- The straightforwardness with which they can be installed and subsequently maintained

Owing to these physical characteristics, aluminium profiles serve as an exceptional choice across a diverse spectrum of applications spanning multiple industry sectors.

Aluminium frames facilitate rapid assembly, alteration, and dismantling. This adaptability proves particularly beneficial for projects where structures must regularly undergo configuration changes. Aluminium’s malleable properties provide unparalleled flexibility in design within complex or specially tailored structural framing ventures.

Lightweight and Durable

Aluminium alloys are recognised for their exceptional lightweight yet robust characteristics. These properties make aluminium ideal for situations where maintaining strength while reducing overall weight is crucial. Typically, the weight of framing constructed with aluminium material is just one-third that of steel frames, offering a significant advantage when numerous components and materials are necessary in designs.

The notable high strength-to-weight ratio of aluminium guarantees both resilience and lasting structural stability. Aluminium profiles can deliver structural integrity up to double that which would be provided by steel frameworks at equivalent weights, making them suitable for various applications.

Corrosion Resistance

The ability of aluminium profiles to resist corrosion and rust is a major advantage, promoting their longevity while requiring minimal upkeep. The natural formation of an oxide layer on aluminium alloys bolsters their capacity to withstand corrosive conditions. This makes them well-adapted for use in demanding environments. The application of protective layers such as powder coating or anodizing can greatly boost the anti-corrosion properties of aluminium frames.

Especially when it comes to architectural-grade anodised coatings, aluminium profiles demonstrate robust resistance against various corroding elements including rainwater and chemicals, ensuring enhanced durability in diverse settings.

Versatility and Flexibility

The design versatility and flexibility offered by aluminium profiles are said to be unmatched. They can be easily shaped and formed, offering significant versatility in design and construction. Advanced technology has enabled aluminium extrusions to be used in projects once thought impossible, such as high-strength applications with weight limitations.

The modularity of aluminium framing systems allows for easy adjustment, making them suitable for setups requiring frequent modifications. Some advantages of aluminium framing systems include:

- Easy adjustment

- Suitable for setups requiring frequent modifications

- Hollow sections provide space for internal installations such as electronics

- Perfect for lightweight structures

This allows space for personalisation and customisation. With more sectors building specialised and contemporary pieces, the demand for customised framing is growing rapidly.

Applications of Aluminium Profiles in Structural Framing

Due to their robustness, enduring nature, and low mass, aluminium extrusion profiles have become a popular choice across multiple sectors, offering an advantageous substitute for plastic materials.

Examining the primary uses of these aluminium profiles within structural framing reveals their significant role.

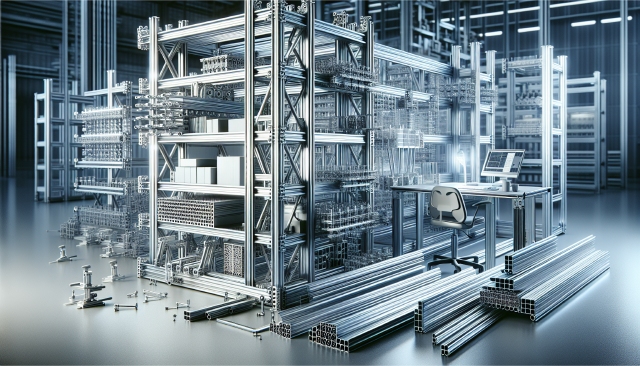

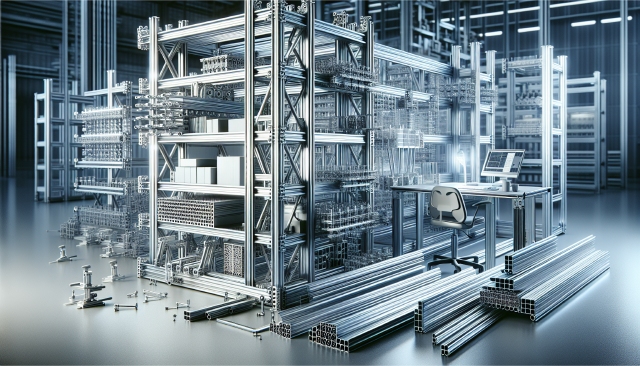

Industrial and Commercial Projects

Within the industrial realm, aluminium profiles are commonly employed for building robust and sizeable rack systems as well as ergonomic workstations due to their notable strength and endurance. For example, modular structures such as extensive rack systems found in commercial environments often incorporate T-slotted aluminium profiles.

The automation industry also takes advantage of these aluminium profiles in assembling conveyor systems, cranes, and industrial robots. This demonstrates their wide-ranging adaptability and consistent dependability across various applications.

Residential and Architectural Uses

Aluminium profiles are frequently utilised in various parts of residential and architectural settings, such as in the construction of window frames, door frames, and curtain walls. This is due to their significant strength, resistance to corrosion, and flexibility, which render them perfect for these applications.

In particular, when it comes to curtain wall facades within these settings, typical aluminium profiles that are employed encompass:

- Mullions

- Transoms

- Perimeter trims

- Wall panels

The diversity in the application of aluminium profiles is thus exemplified by their use across different components within residential and architectural environments.

Transportation and Aerospace Industries

Aluminium profiles, known for their lightweight characteristics, are perfectly suited for the transportation and aerospace sectors. They play a pivotal role in creating structures that are both light and sturdy. The construction of aircraft structures within the aerospace industry heavily relies on aluminium profiles because they offer durability while minimising weight.

In a similar vein, these aluminium profiles find significant application in the automotive industry by being integral components of vehicle frames and chassis. Their incorporation helps to diminish overall vehicle weight, which consequently enhances fuel efficiency.

Design Considerations for Aluminium Framing

When crafting structures using aluminium profiles, it’s crucial to meticulously assess their particular ability to bear loads, utilise connection technology that guarantees robust and stable constructions, and consider the possibilities for customising these elements.

Load-Bearing Capacity

Grasping the load-bearing capabilities of aluminium profiles is crucial for maintaining structural integrity and ensuring safety in any design. These profiles exhibit varying stress deformations, which are influenced by their wall thickness and cross-sectional shape. Thus, to fully comprehend their ability to bear loads, it’s vital to compute these deformations.

Selecting an appropriate wall thickness is key—a decision guided not only by strength needs but also by cost-effectiveness goals.

Connection Technology

The technology behind the connections in aluminium framing systems is vital for creating robust and steadfast constructions. These advanced systems employ brackets that lock mechanically, offering enhanced durability. For demanding applications, innovative extrusion systems made of high-strength materials are being developed with assembly plates featuring precision engineering and V-shaped bosses that hold patents pending status, which transform joints based on friction into bonded structural connections.

Aluminium framing systems come equipped with built-in screw channels to facilitate easy connection solutions.

Customisation Options

Aluminium profiles offer significant customisation opportunities, enabling them to be tailored to precise design specifications through processes like cutting, drilling, and applying various finishes.

In numerous countries, there is a growing trend toward adopting striking custom colours for aluminium profiles. This approach aligns with architectural designs and serves to increase their visual attractiveness.

(S. H. Chooi Sdn Bhd provides comprehensive customisation services. More at the end.)

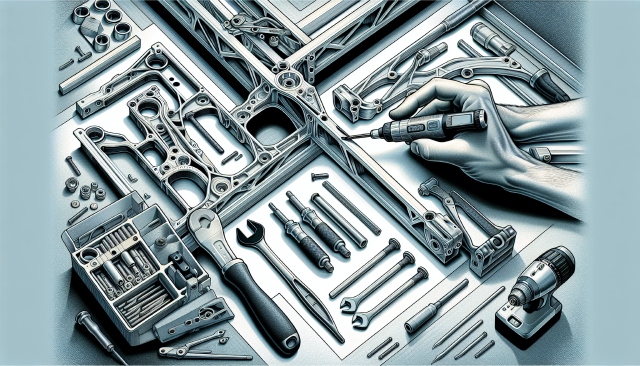

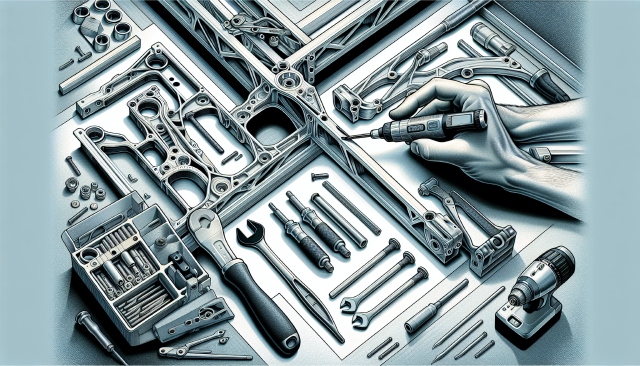

Installation and Assembly Tips

The process: It is imperative to meticulously plan and execute the installation and assembly of aluminium frames from start to form. Ensuring exact measurements and proper levelling of the frames prior to starting the installation process is essential in order to prevent any issues with alignment. It’s necessary to don suitable protective equipment, including gloves and eyewear, while managing and putting together aluminium profiles.

Environmental Impact

Utilizing aluminium framing in construction projects serves a dual purpose. It offers robust structural support and also provides environmental advantages. The ability to recycle aluminium frames contributes to the reduction of carbon emissions, thus diminishing the energy requirements and ecological impact of such developments.

Significantly, the cost associated with electric power accounts for approximately 20 to 40 percent when producing aluminium. This underscores the critical role that energy efficiency plays within the production process of this material.

Case Studies and Real-World Examples

Observing the application of aluminium profiles can offer meaningful understanding of their capabilities. The material’s adaptability and dependability have been proven across diverse sectors through its incorporation into structural framing undertakings. One notable example includes a factory that re-engineered the frame of a forklift from steel to aluminium, which resulted in increased load capacity as well as improved safety and durability.

In numerous successful endeavours, including extensive rack systems and ergonomic solutions for managing materials within production settings, aluminium profiles have demonstrated their effectiveness.

Bosch Rexroth Solutions

Bosch Rexroth demonstrates the adaptability and effectiveness of aluminium profiles through actual use cases, such as their ergonomic lifts that are combined with Kanban flow racks. This particular system is designed to alleviate the strain on workers while guaranteeing a seamless supply of materials. The company’s Kanban flow racks function either as central storage units similar to supermarket shelves or as containers supplying workstations, all while being tailored for maximum cost efficiency and long-term application.

The material shuttles offered by Bosch Rexroth are engineered to facilitate a connection between these central storage shelves and individual workstations or production areas, promoting an orderly approach to Kanban replenishment and enhancing the efficiency of operations.

S.H. Chooi Fasteners

For more than 40 years, S.H. Chooi Fasteners in Penang, Malaysia has specialised in supplying high-quality fasteners specifically designed for aluminium profiles. Their extensive experience and knowledge stand as evidence to the reliability and effectiveness of these aluminium profiles across a multitude of applications.

Expert Insights and Recommendations

Professionals in the industry advocate for a comprehensive grasp of aluminium profiles’ fundamental properties, including their combination of lightness and strength, to optimise their use in structural framing. These experts highlight the necessity of employing appropriate accessories and cutting-edge connection technology to achieve robust and reliable aluminium constructions.

Leaders in development point out that embracing innovative design approaches—like modular systems that can be reconfigured using aluminium profiles—is considered best practice by specialists.

Industry Experts’ Advice

Experts in the industry have imparted essential knowledge about optimal methods for employing aluminium profiles within various applications of structural framing. They advocate for the adoption of aluminium profiles within modular construction owing to their simplicity in assembly and versatility regarding design alterations.

The use of aluminium profiles in modular building projects facilitates swift and effective construction, while simultaneously granting the capacity to modify designs according to requirements as they arise.

Future Trends

Prospects for aluminium profiles appear to be on the upswing thanks to a number of developing trends. Due to the rising uptake of solar energy coupled with improvements in aluminium alloys, substantial growth is anticipated in the market for PV Aluminium Frames.

Aluminium alloys that are not only lightweight but also highly resistant to corrosion are improving both the efficiency and longevity of solar panels. There’s an increasing move towards frameless designs where aluminium frames are integrated within solar panels themselves, offering a streamlined and visually appealing look.

Summary

The utilization of aluminium profiles for structural framing has become widely recognized as reliable and adaptable across multiple sectors, owing to their superior strength-to-weight ratio, resilience against corrosion, and the capacity for flexible design. These attributes render them a prime material selection. Provided that there is meticulous attention paid to design details, precise execution during installation, and consistent maintenance thereafter. Aluminium frameworks can offer enduring and eco-friendly options suitable for diverse applications. Looking ahead, the progressive incorporation of these profiles within new industry areas promises to revolutionise our constructional methodologies and architectural blueprints.

Frequently Asked Questions

What are aluminium profiles?

Aluminium profiles, recognised for their exceptional strength-to-weight ratio, serve as materials in the construction of contemporary buildings, vehicles, and industrial machinery. These profiles are ideal for fabricating structures that are both sturdy and light in weight.

What are the benefits of using aluminium in structural framing?

Incorporating aluminum into the structural framing of projects affords advantages like reduced weight, robustness, and resistance to corrosion, yielding enhanced design versatility for complex or bespoke endeavors.

What are some applications of aluminium profiles in structural framing?

A variety of industries—including industrial, commercial, residential, architectural, aerospace and transportation—utilize aluminium profiles for structural framing purposes across a broad spectrum of applications.

What are some design considerations when using aluminium for framing?

It is essential, when opting for aluminum in the context of framing, to take into account its capacity to bear loads, the technology employed in connecting components, and the possibilities it offers for tailor-made solutions. Doing so guarantees that both structural integrity requirements and specific customization demands are adequately fulfilled.

How can I maintain and ensure the longevity of aluminium frames?

It is essential to perform consistent maintenance, such as inspections and cleaning, to guarantee the extended durability of aluminium frames.

Promptly attending to any indications of deterioration is equally vital in averting additional harm.

Customisation Services

Here at S. H. Chooi, we understand the highly-customisable nature of aluminium and the ever increasing rate of specialised machinery. Trust S.H. Chooi Fasteners with your industrial needs! Contact us today at +604 – 399 6468.