Services

Dedicated Inventory Programs by S. H. Chooi

In the ever-evolving landscape of manufacturing and supply chain management, efficient inventory management is paramount. Companies strive to balance the delicate act of maintaining adequate stock levels to meet production demands while minimising excess inventory that ties up valuable resources. At S. H. Chooi, we are committed to providing solutions that streamline these processes through innovation and automation with dedicated inventory programs, leveraging cutting-edge systems like Kanban and Vendor Management Systems (VMS).

Kanban Systems

A Proven Approach to Lean Manufacturing

The Kanban system, rooted in the principles of lean manufacturing, was pioneered by Toyota in Japan and has since been embraced by manufacturers worldwide. Various types of equipment, such as overwrapping machines, weigh scales, tray sealers, bagging equipment, labelling systems, liquid filling machines, strapping machines, shrink wrappers, packaging automation machines, and packaging lines, play a crucial role in the Kanban system. This visual workflow management method optimises production processes by ensuring a smooth flow of materials and reducing waste. At its core, Kanban relies on visual cues, such as cards or bins, to signal when more materials are needed in the production process.

Kanban Systems

Key Features

- Visual Workflow: The Kanban system makes the flow of work visible, allowing for easy monitoring of task statuses and identifying bottlenecks quickly.

- Work in Progress (WIP) Limits: By limiting the number of tasks being worked on simultaneously, the system prevents overburdening and enhances focus and efficiency.

- Smooth Flow Management: Kanban ensures a steady flow of tasks through the production process, minimising delays and interruptions.

- Explicit Process Policies: Clear rules for task handling are defined and communicated, ensuring everyone is on the same page.

- Continuous Improvement: Regular feedback loops are implemented to review and adjust the process based on real-time performance data, highlighting the benefits of using Kanban systems.

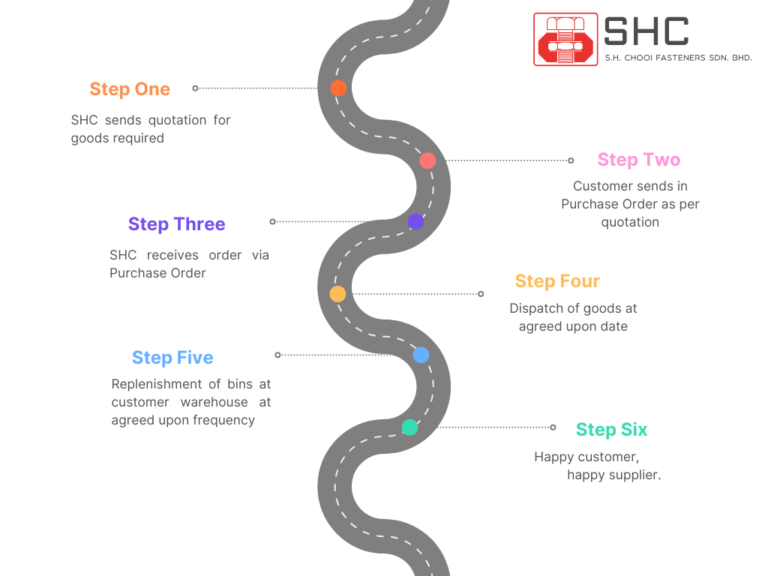

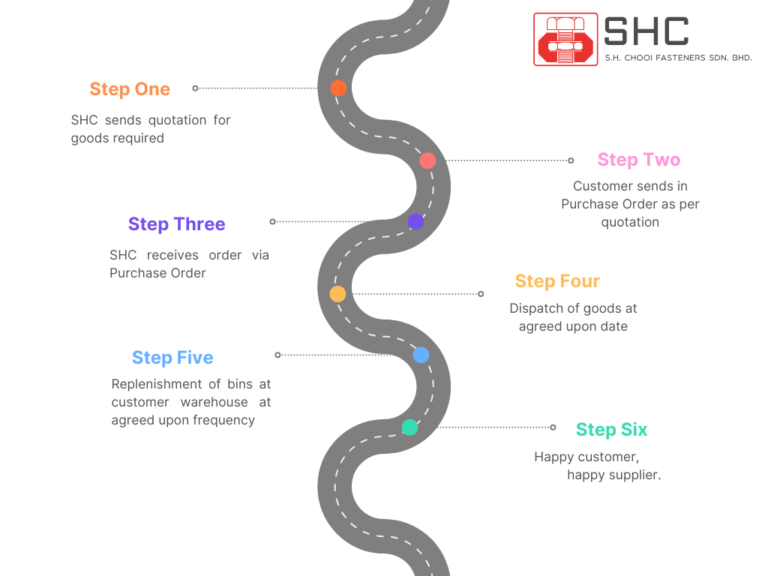

Our Two-Bin Kanban System

At S. H. Chooi, we apply the Kanban system through a two-bin approach, tailored to meet the specific needs of our clients. Here’s how it works:

Bill of Materials (BOM)

Clients provide us with a BOM list, detailing the ingredients required for their production lines.

Customisable Racks

We fill both faces of a customisable rack with the items listed in the BOM. Each bin is equipped with a barcode representing the part number.

Usage and Replenishment

When one side of the rack is depleted, the production line switches to the other side. Our team promptly replenishes the empty side, ensuring an uninterrupted supply of materials. Various machines, such as packaging machines and sealing machines, play a crucial role in the Kanban process by efficiently handling and replenishing materials.

Software Integration

The racks can be connected to the client’s internal software system. Operators simply scan the bin’s barcode when it is empty, automatically notifying the system for replenishment.

This approach guarantees that production lines never face shortages, maintaining seamless and efficient operations.

Application in Various Industries and Packaging Systems

Our dedicated inventory programs are not limited to a single industry. We cater to a diverse range of sectors, ensuring that each client receives a tailored solution to meet their unique needs.

Conclusion

Dedicated inventory programs at S. H. Chooi are designed to optimise manufacturing processes through the integration of Kanban systems and Vendor Management Systems. By providing customised solutions that address both internal workflow management and external supplier coordination, we ensure that our clients experience minimal disruptions and maximum efficiency in their operations.

To learn more about our inventory programs and how we can tailor them to your specific needs, visit our website or contact us directly. Let S. H. Chooi be your partner in achieving streamlined, lean, and efficient production processes.

By combining the strengths of Kanban and VMS, S. H. Chooi delivers innovative and reliable inventory solutions that empower businesses to thrive in a competitive market.